This Page is Home![]() Sustainability

Sustainability![]() Social

Social![]() Quality Management

Quality Management

Quality Management

Principle of Quality Activities

- Demonstrate flexible ideas and creativity to provide high value-added products and services.

- Establish an appropriate construction management system for construction work.

- Strive to improve the ability of the staff to perform their duties, refine productivity-enhancing technologies, and strive to ensure reliable construction and quality.

Click here to view the Safety, Health, Quality, and Environment Policy

Promotion System

Our quality management system conforms to ISO 9001 standards.

The quality management system is controlled by the Quality and Environmental Management Committee, established under the Sustainability Promotion Committee chaired by the President and Representative Director, and applies to all POC's business activities (construction activities and business activities in our offices).

We formulated the "Integrated Manual" that outlines the rules and procedures for corporate management in conformity with the certified quality management system and environmental management system, and implement it across the organization.

In addition, we continuously provide awareness training sessions to employees, including management system training for young employees.

Quality Management System

In March 1997, the Civil Engineering Business Unit of Yokohama Branch obtained ISO 9001 certification, and in March 2000, all branches obtained certification individually. In November 2003, our quality management system received ISO 9001 certification as a company-wide system.

We will continue to utilize our management system in order to promote continuous system improvement and efficient and effective operations.

For a list of our ISO certifications, click here

Quality Patrols

To ensure reliable quality that meets client requirements, a quality plan, which outlines quality-related activities for each construction project, is prepared and managed by the project supervisor. The Civil Engineering Division Manager and Building Construction Division Manager at each branch regularly conduct quality patrols to verify the effective implementation of the plan and the proper functioning of measures to prevent nonconformities.

Commitment to Customer Satisfaction

We conduct customer satisfaction surveys every year in accordance with our quality management system. We collect and analyze survey data and construction performance evaluations, and share the findings, such as items that received high ratings and those that were rated poorly, with each branch and construction office through meetings such as the Civil Engineering Division Managers' Meeting and the Site Manager/Senior Staff Member Meeting. In particular, for items that received low evaluations, we clarify the causes and implement countermeasures to build a system that enables company-wide improvements, aiming to further enhance customer satisfaction.

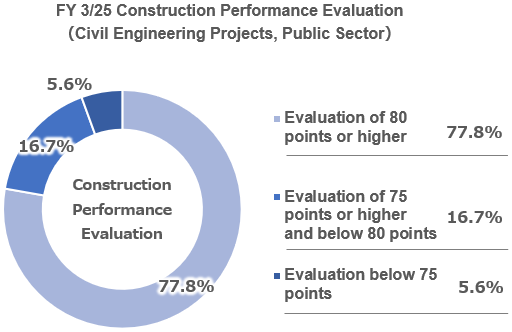

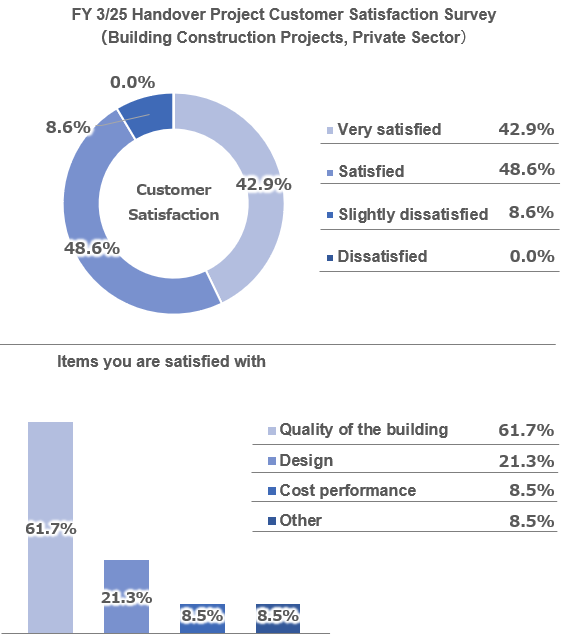

In the FY 3/25 survey, for public civil engineering works, approximately 95% of our work received very high client evaluations of 75 points or more. For private building construction, many customers expressed satisfaction with our constructed buildings, construction staff, and sales staff, rating them as "very satisfied" or "satisfied."

In addition, we also received high evaluations regarding the quality, design, and cost performance of the buildings.

We will strive to provide high-quality structures as a matter of course, while placing high priority on safety, health and environmental issues.

Delivering High-quality Buildings and Infrastructures

Toyosu Senkyaku Banrai is a large complex built around the themes of "eating" and "relaxing", developed on a site adjacent to the Toyosu Fish Market.

The facility consists of a high-rise hot spring building with an open-air bath, foot baths and a hotel etc., and low-rise commercial buildings reminiscent of the streetscape of old Edo (erstwhile Tokyo). It was a highly complex project with many constraints to construct narrow rectangular buildings very close to the property lines of the site, which had an approximately 4m height difference. Due to the complex building structure, each floor was constructed simultaneously. Given that the project had attracted significant industry attention, the construction progressed with close care and attention to the great detail, holding regular counterparty discussions and ensuring their full cooperation in various phases. Another focus was establishing smooth communication among on-site personnel. This was achieved by visualization of construction plans by utilizing BIM, labor-saving by adopting pre-casting of structures, and giving precise work orders per tablet terminals.

The facility became a venue enjoyed by many tourists and local residents as the name "Senkyaku Banrai" (a place where thousands gather) suggests. As a new destination in Tokyo and a great addition to the Toyosu Fish Market, the facility will make a contribution to the further development of the local area.