This Page is Home![]() Sustainability

Sustainability![]() Social

Social![]() Occupational Health and Safety

Occupational Health and Safety

Occupational Health and Safety

Principle of Health and Safety Activity

- Make every effort to avoid all accidents, including occupational accidents and public ones

- Prevent occupational diseases, infectious diseases, and personal injuries and illnesses, promote mental and physical health, and create a comfortable and reassuring working environment.

- Build an open workplace culture, conduct safety and health activities where staff and business partners are united, and aim to improve the standards.

Click here to view the Safety, Health, Quality, and Environmental Policy

Promotion Structure

Environment Health and Safety Committee

To effectively promote environment, health and safety activities, the Environment Health and Safety Committee is established as the central organization under the Sustainability Promotion Committee chaired by the President, CEO and Representative Director. This committee deliberates and decides on basic policies and measures. Furthermore, based on the annual plan, the Environment Health and Safety Committee conducts patrols of construction sites at all branch offices.

Occupational Health and Safety Management System (COHSMS)

Our commitment to construction safety stems from basic respect for humanity. In order to eliminate or reduce potential disaster factors inherent in our business, promote health promotion and the creation of comfortable workplaces for workers, and improve the company's safety and health standards, we have established an occupational health and safety management system. We were one of the first in the construction industry to obtain the "COHSMS Certification" from the Japan Construction Occupational Safety and Health Association (JISHA) in 2008, and have been updating it every three years through audits.

Following the revision of the COHSMS Guidelines to "NEW COHSMS" by the Japan Construction Occupational Safety and Health Association in April 2018, we revised at our end our management system by including the addition of mental health initiatives. While adhering to the standards in the above certification, we will aim at further enhancement of the system and co-work with our subcontractors to ensure its implementation and operation. By improving the level of safety and health management, we will strive to take preventive measures to avoid occupational accidents.

Several of our overseas offices have acquired the international standard for occupational health and safety management systems (ISO 45001), and we are working to continuously improve our occupational health and safety performance through the operation of the system.

* COHSMS: Construction Occupational Health and Safety Management System

External audits

| COHSMS certification scope | : Headquarters and 10 domestic branch offices |

| ISO 45001 certification scope | : Singapore, Hong Kong, and Indonesia |

For a list of our ISO certifications, click here

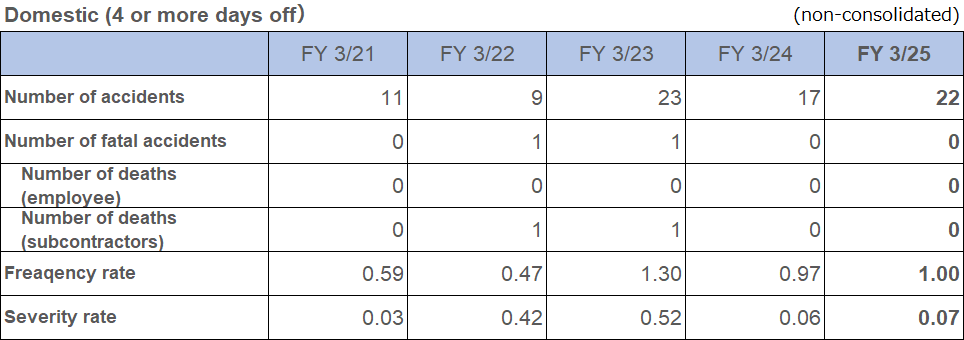

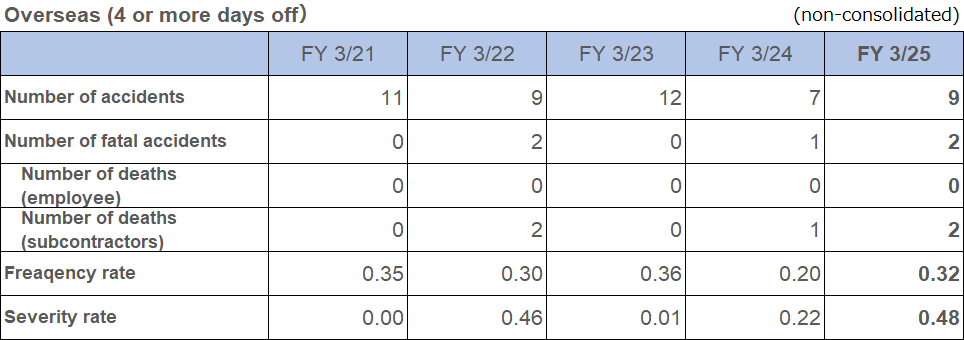

Safety Results

All numbers are non-consolidated figures (POC only)

* Frequency rate indicates the frequency of accidents. Number of fatal causalities due to occupational accidents/total number of actual working hours x 1,000,000

* Severity rate indicates the severity degree of an accident. Total number of lost working days/ total number of actual working hours x1,000

* Accidents causing 4 or more days lost

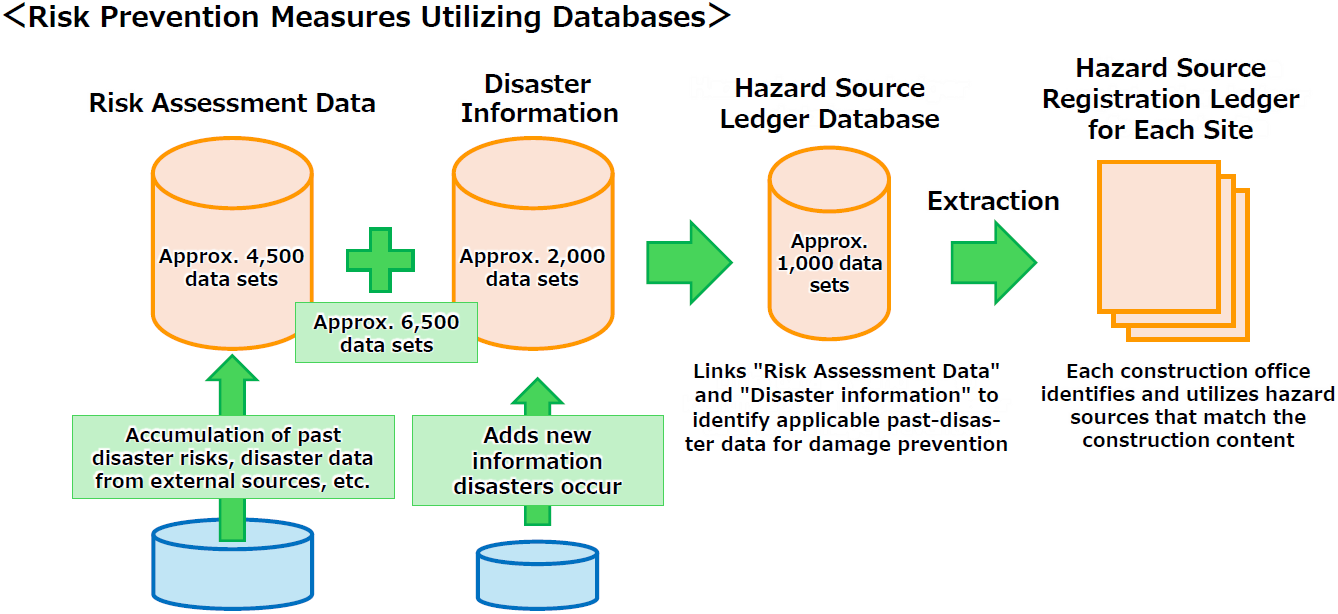

Risk Assessment

Based on approximately 6,500 data items created from risk assessment data and accident information, we have identified and registered about 1,000 high-risk hazards in a database, which is used for risk assessment. In site offices, we use this database to identify risk factors, which are then shared with subcontractors, in each phase of work and during the project planning. The risk factors identified through above risk assessment are linked to disaster information, and situational photos and maps from actual disaster records are used to determine risk reduction measures. Thus, we are working together with our subcontractors on disaster prevention measures to avoid the same disaster scenarios.

On-site Initiatives for Putting Safety First

Education & Awareness

To enhance knowledge and skills related to workplace safety and to work toward eliminating accidents, we provide systematic, rank-based training for all employees from the time they join the company, as well as ongoing education such as regular training sessions for general safety and health managers.

Global Implementation of POC Standards

We have been implementing occupational accident prevention and quality management measures that prioritize safety and quality in Japan, and named it the Penta-Ocean Construction Standards. We spread these standards not only in Japan but also overseas and carry out occupational accident prevention activities in collaboration with subcontractors.

<Examples of Initiatives>

- Establishment of Special Safety Day (March 30), Fire Prevention Day (April 20)

- General Safety Meeting (1st day of every month), Safety Week (preparation period: June 1-30, period held: July 1-7)

- Implementation of Penta-Ocean Construction self-regulation and accident prevention activities (Exercise 333, etc.)

Designating a Special Day to Pledge Safety

Special Safety Day (March 30)

On March 30, 2014, a major accident occurred in the Okinotorishima port construction site, taking precious lives of seven people. Every year on March 30, a memorial service is held with the attendance of the bereaved families and clients. In addition, to keep this disaster in mind, March 30 is designated as "Special Safety Day," when simultaneous onsite inspections are conducted to reconfirm safety.

Fire Prevention Day (April 20)

On April 20, 1998, a major fire occurred at our construction site, with one deceased, 16 people mildly/seriously injured, and one building completely burned down. Taking this accident as a lesson, we designated April 20 as Fire Prevention Day to reconfirm fire prevention measures.

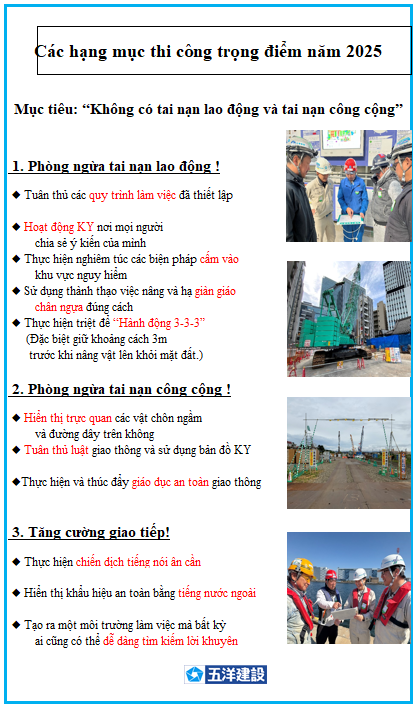

Safety Considerations for International Workers

The proportion of international workers has been increasing year by year, and they account for about 10% of on-site personnel at our domestic sites. As part of our safety measures for non-Japanese personnel, we prepare safety signage, key construction items, and orientation/training materials in their native languages (such as Vietnamese, Indonesian, English, and Chinese), and provide training accordingly.

key construction rules

Initiatives to Prevent "Specific Accidents"

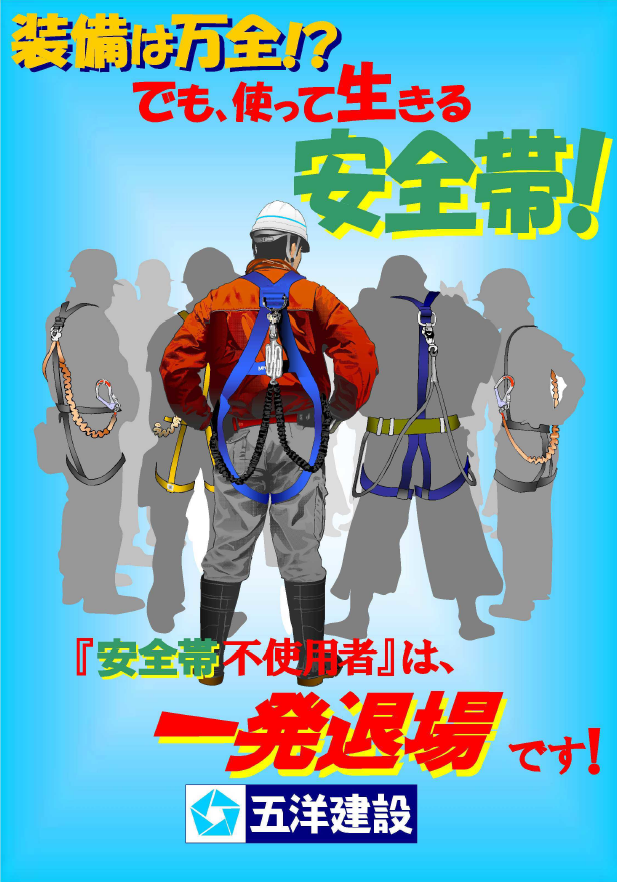

We have designated crash accidents, fall accidents and heavy machinery (crane) accidents as "Specific Accidents" and focus our efforts for preventing these accidents amongst all other accidents. Regarding the prevention of crash and fall accidents, we introduced a "Immediate 'Red Card' System for Workers Who Do Not Use Safety Belt*1," which suspends a worker from the construction site when he/she is found not using a fall prevention equipment (commonly, a safety belt) in a place where a safety belt is mandatory. As for the prevention of heavy machinery and crane accidents, we enforce the "Zero Heavy Machinery Accident Declaration" to reconfirm prohibition of entering a working radius of the equipment, and to assign guards to prevent any entry. Also, we enforce the "Zero Crane Accident Declaration," "Exercise 333*2."

*1 Workers who were suspended will return to the site after receiving the safety training again.

*2 Exercise 333: (1) 3 m away from the suspended load when slinging. (2) Stop hoisting the lifted load at 30 cm.

(3) Roll up after counting 3 seconds when hoisting the lifted load (introduced in 2008).

Strengthening Communication

Compassionate and Friendly Greeting Campaign

Since 1998, we have been promoting the Compassionate and Friendly Greeting Campaign. We make every construction staff to call each other by name for deepening the sense of fellowship and communication, aiming to create a safe, healthy, and vibrant workplace culture with open communication, and achieve "zero accidents, zero disasters, and zero illnesses."

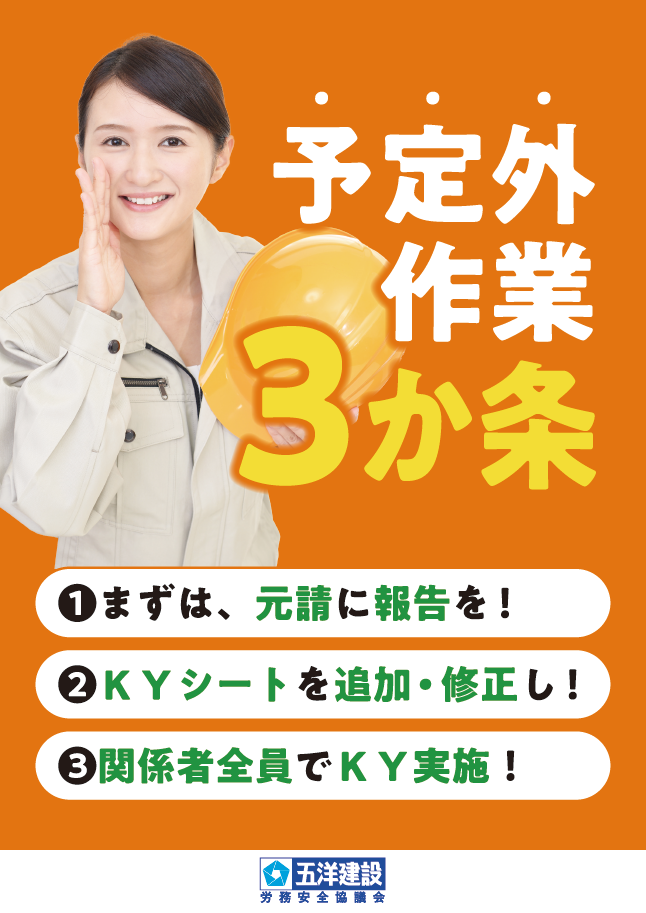

Thorough Coordination and Communication between Work Tasks

In principle, unscheduled work is prohibited. If unscheduled work must be performed, we have established the following procedures to ensure thorough coordination and communication between work tasks.

- Temporarily suspend work and report to the prime contractor

- Review procedures, etc., and create a "Record of meeting for unscheduled work"

- After obtaining approval from the prime contractor, inform the workers and conduct an on-site risk assessment

We also display posters to make employees aware that unscheduled work is prohibited.

Safety as a Top Priority

We are engaged in various health and safety promotion activities to eliminate occupational accidents.

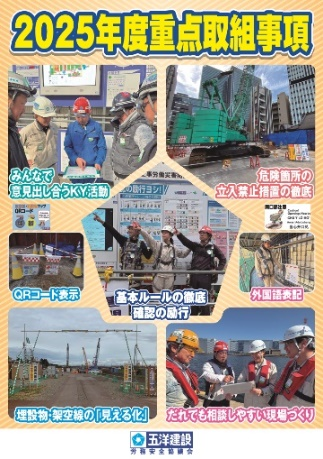

Examples of Initiatives in FY 3/25

Tokyo Building Construction Branch: Emergency patrol for preventing heatstroke conducted by the Head of the Labor Standards Department, Tokyo Labor Bureau (May 21, 2024)

For the Tsukishima 3-chome North District Type 1 Urban Redevelopment Project, an emergency patrol for preventing heatstroke was conducted by the head of the Labor Standards Department, Tokyo Labor Bureau. The Head of the Labor Standards Department said, "Effective communication among staff, foremen, and workers was well maintained. Please ensure to foster an environment to encourage workers to report physical discomfort due to heatstroke."

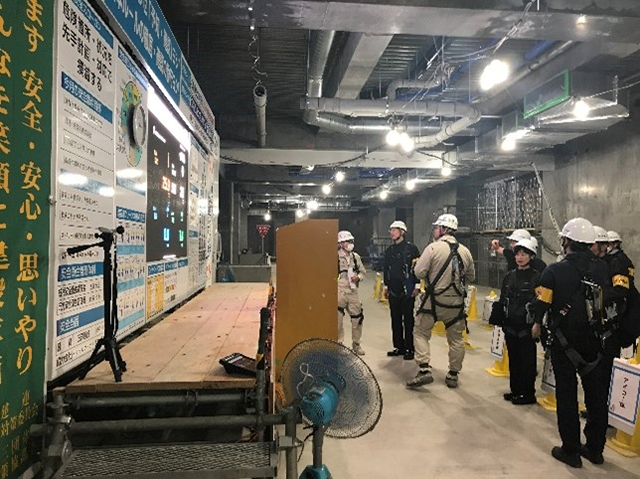

Sapporo Branch: Patrol Conducted by Environment Health and Safety Committee (August 27, 2024)

For the Hokkaido Shinkansen Oshamambe Station Viaduct construction project, a patrol was conducted by six members of the Environment Health and Safety Committee, including the Vice President and Head of the Safety, Quality and Environment Management Divisions Group. Each committee member provided guidance such as "It is good to see that work areas and separation of pedestrian and vehicle paths are clearly visualized. Since there are many foreign workers, please make efforts to prevent accidents by ensuring that all workers can visually understand the site rules."

Singapore and Hong Kong Sales Offices: Safety training conducted in Tokyo for Staff Members from Singapore and Hong Kong (June 3-6, 2024)

We welcomed three overseas staff responsible for safety management from Singapore and Hong Kong to Tokyo to receive safety management training. By observing morning meetings at sites and inspecting the latest safety equipment, participants experienced Japan's high standards of safety awareness and innovative site management practices, including meticulous organization and cleanliness. They also deepened their understanding of our Company's history and technology through discussions with the Safety, Quality and Environment Management Division and visits to the Institute of Technology and Penta-Ocean Museum. This training content is shared at international sites and is contributing to further raising safety awareness within the International Business Unit.

View Safety First Activities (by Fiscal Year, Japanese only)

Initiatives in Partnership with Subcontractors

Penta-Ocean Construction Labor Safety Council

In order to ensure safety and health together with our subcontractors, we have organized the Penta-Ocean Construction Labor Safety Council which consists of 1,126 member companies (as of April 2025). The Labor Safety Council works to improve knowledge levels and skills regarding labor safety and carries out various activities to prevent accidents and create a foundation for smooth cooperation between POC and subcontractors.

Safety and Health Patrols

Based on an annual plan, regular patrols are conducted jointly by headquarters, branch offices, and subcontractors. In addition, safety and health patrols in which the President and CEO participates are conducted twice a year.

Safety, Health and Environment Promotion General Meeting

In June, the headquarters, branch offices, and the Labor Safety Council jointly hold a "Safety, Health and Environment Promotion General Meeting." This is in preparation for the National Safety Week, which is held every July. The Safety, Health and Environment Promotion General Meeting at headquarters in FY 3/26 was held jointly with the Labor Safety Consultation Council Federation, with the President, CEO and Representative Director in attendance.

Education and Training Programs

We hold various education and training programs, such as foreman and safety and health manager education, safety officer training, risk sensitivity education, top seminars of the Labor Safety Consultation Council Federation, and business owner education, to enhance the knowledge and skills of our members.

For education at the Safety and Quality Control Education Office, click here

Excellent Foreman Certification System

In FY3/14 we introduced an Excellent Foreman Certification System to "secure and train future leaders" and to "improve the treatment given to construction engineers." Certified excellent foremen are provided with a certain amount of excellent foreman benefit according to the number of days worked at our sites, and those whose annual working days exceed 100 days receive an additional benefit. In addition, the employer's share of social insurance premiums for allowances is paid separately. In FY3/25, 520 foremen including 92 newly certified foremen were certified as excellent foremen.

Foremen's Associations

At each site, we organize foremen's associations, consisting of foremen and safety and health managers from multiple subcontractors, and carry out activities to raise safety and health awareness among all workers.