This Page is Home![]() Sustainability

Sustainability![]() Environment

Environment![]() Environmentally Conscious Design and Construction

Environmentally Conscious Design and Construction

Environmentally Conscious Design and Construction

Environmentally Conscious Design

In the design field, in addition to considering whether the design work meets the needs of society, including customers, and whether it can be provided at the minimum cost, the design department also considers whether it is possible to create a design that is environmentally conscious. We are considering this from this perspective.

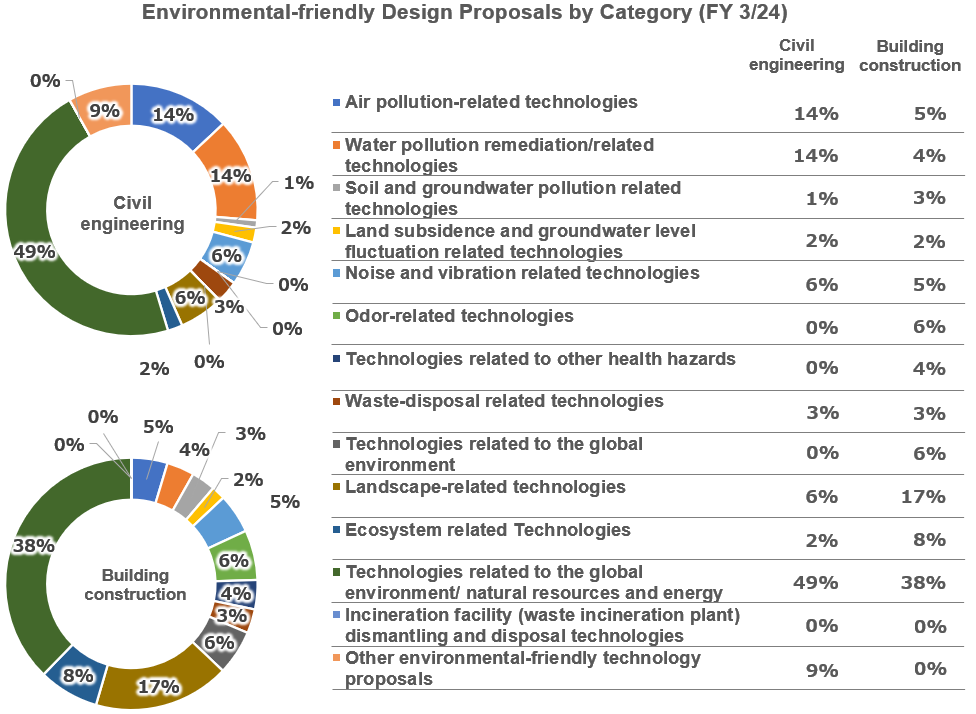

In the civil engineering department, in the design of 20 properties, we focused on "Technologies related to the global environment/ natural resources and energy," "Water pollution remediation/related technologies," "Air pollution-related technologies," "Noise and vibration related technologies," and "Landscape-related technologies." We made 139 environmentally conscious design proposals.

The architecture department proposed a total of 350 environmentally conscious design items in the design of 13 properties. Looking at the proposal content by field, the proportions of "Technologies related to the global environment/ natural resources and energy" and "Landscape-related technologies" remained unchanged from last year, accounting for approximately 60% of the total. There were no significant changes in the proportions of other fields.

Green Design and Construction

Zero Energy Buildings (ZEB)

In light of the target to achieve carbon neutrality by 2050, the clients' awareness of energy conservation and the use of renewable energy is continuously rising. In this context, we are promoting active proposal of the application of Zero Energy Building(ZEB) technologies.

Our target for FY 3/26 is increasing the percentage of ZEB buildings to 50% or higher of all design/consulting projects undertaken by POC.

<Obtained ZEB Planner certification (January 2020)>

The certifier, Sustainable Open Innovation Initiative (SII), registers corporations that provide consultation services and business support for designing ZEB and other energy-efficient buildings. We will continuously make ZEB conversion proposals, subsidy applications, etc. to our clients.

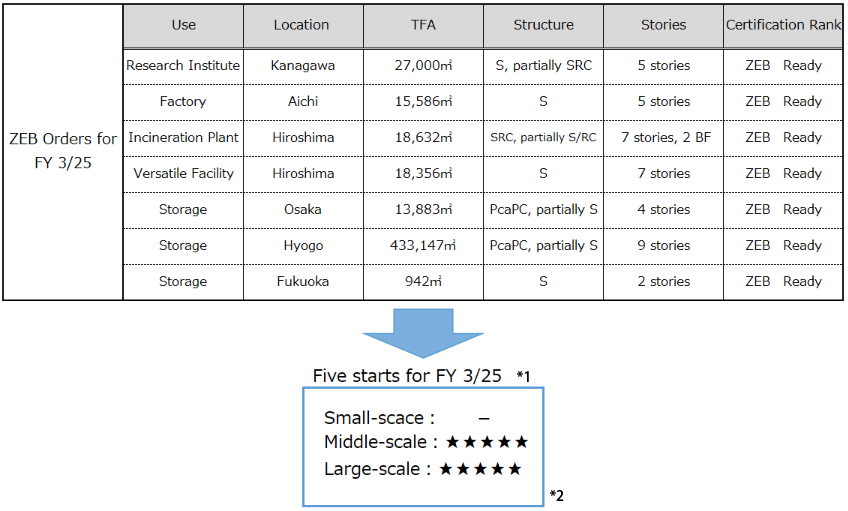

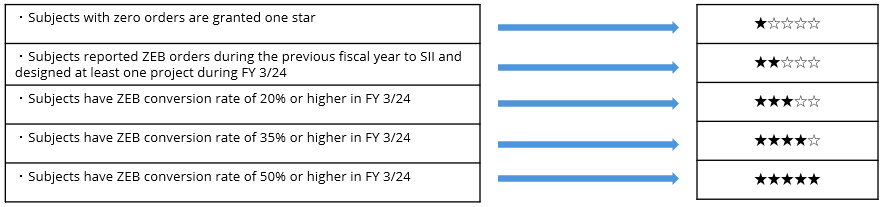

In addition, SII introduced a ZEB Planner evaluation system, where they evaluate registered corporations in proportion to their announced orders received during FY 3/25 and report of orders received, with a maximum 5-star rating for each building size (TFA).

*1 Evaluation values calculated by POC using the following method

*2 Calculation method of ZEB conversion rate

·For middle-scale (between 300 m2 and 2,000 m2) & small-scale (up to 300 m2) buildings :

ZEB conversion rate = (Number of ZEB projects designed in a single year)/ (Number of all projects designed in a single year)

·For large-scale (2,000 m2 and larger) buildings :

ZEB conversion rate = (TFA of ZEB sections designed in a single year) / (TFA of all buildings designed in a single year)

BELS Certification

BELS is an abbreviation for Building-Housing Energy-efficiency Labeling System, a system in which a third-party organization evaluates and certifies the energy-saving performance of new and existing buildings. The rating is indicated with 6 stars according to the performance of the building.

What is a ZEB?

Zero Energy Building, pronounced "zebu" in Japanese, refers to a building that aims to reduce the annual primary energy consumption the building to zero while achieving a comfortable in-building environment. Energy consumption cannot be completely reduced to zero only through every saving because of human activities inside the building. We strive to achieve zero consumption on a net basis by supplementing the used energy with newly created energy.

<Methods>

Exterior wall specifications: Reinforced roof insulation

Air conditioning equipment: Use of highly-efficient equipment and application of segmented operation control

Ventilation equipment: Use of highly-efficient ventilation fans, CO2 sensor operation control

Elevators: Addition of power re-generation function

Energy creation: Solar power generation

ZEB Conversion of a Factory and Hydrogen Energy Demonstration

In our attempt to achieve carbon neutrality by 2050, we are conducting verifications at our own facilities to promote the use of renewable energy and the creation of highly energy-efficient buildings.

While offshore wind power is receiving increasing attention as the driver for the achievement of carbon neutrality, we built "Muroran Factory", which will engage in manufacturing temporary steel structures for offshore wind farms.

To cover all electricity used in the factory and the offices by renewable energy sources, it is equipped with a solar power generation system and a hydrogen power generation system. As a "100% renewable-energy factory", it opened in October 2022. In addition, the office building acquired a BELS ZEB certification by introducing various energy-saving features.

As for the energy creation, a photovoltaic power generation system (output: 670kW) installed on the factory roof and fuel cells (output: 30kw) in the hydrogen generation plant will generate green energy to supply power for the factory operation and all light fixtures.

The facility features a power generation system powered by hydrogen energy, a next-generation power source which attracts significant industry attention. This includes regular monitoring of hydrogen use, measuring its benefits, and developing a control method optimized for power consumption. Moreover, green hydrogen is produced by water electrolysis apparatus (production rate: 3Nm3/h) using electricity from solar power generation, and stored in hydrogen storage alloys (storage capacity: 300Nm3) to generate power using fuel cells to meet the power demand during rainy weather or evening hours. We store byproduct hydrogen purchased from neighboring Hokkaido factories in two 900Nm3 tanks. This hydrogen can meet electricity demands when our green hydrogen supply is low or during Business Continuity Plan (BCP) measures.

All while continuing regular monitoring, we are planning for additional power supply to expand our green hydrogen generation by using surplus solar electricity, through enhancing the water electrolysis apparatus and introducing more fuel cells.

We will continue system operation and monitoring at the new Muroran Factory to accumulate operational data, which will be utilized for further ZEB conversion and more effective hydrogen energy utilization.

In order to achieve carbon neutrality, we will take on the challenge of green energy fields, such as the construction of offshore wind power farms and the ZEB conversion of buildings.