This Page is Home![]() Sustainability

Sustainability![]() Environment

Environment![]() Environmental Management

Environmental Management

Environmental Management

Principle of Environmental Activity

- Reduce CO2 emissions generated in construction business activities (reduction of CO2 emissions from work vessels and construction equipment; productivity improvement through utilisation of ICT, electrification, automation and autonomy; use of low-carbon materials, etc.), and promote ZEB* (energy saving and energy creation) for project offices, thereby contributing to the realisation of carbon neutrality.

* ZEB: Net Zero Energy Building - Strive to achieve carbon neutrality, create a recycling-based society, and create, preserve, and restore the environment, through close communication with local communities, the development of environment-related technologies, and environmentally friendly design and construction.

- Continuously educate the staff and business partners on the importance of environmental conservation activities, and strive to prevent environmental accidents and ensure zero violations of environmental laws and regulations.

Please click here to view the Safety, Health, Quality and Environment Policy

Promotion System

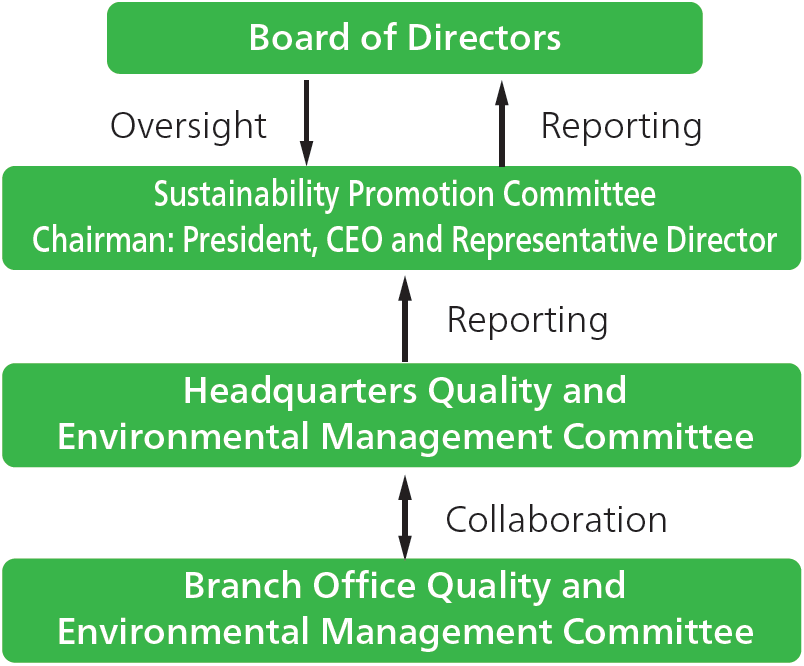

Our environmental management system conforms to ISO 14001 standards. The environmental management system is overseen by the Quality and Environmental Management Committees of the Headquarters and each branch office, established under the Sustainability Promotion Committee chaired by the President, CEO and Representative Director. The system is applied to all of our business activities (construction production activities and office activities). We formulated the "Integrated Manual" that outlines the rules and procedures for corporate management in conformity with the certified environmental management system and quality management system, and implement it across the organization. In addition, we continuously provide training sessions to employees, including management system training for young employees, to inform and educate our employees.

Environmental Management System

In March 1999, the Institute of Technology obtained ISO 14001 certification, and in March 2002, each branch office acquired certification individually.

We obtained ISO14001 certification as a company-wide environment management system in November 2002, and have been operating it as a means to promote continuous system improvement and efficient, effective operations.

For a list of our ISO certifications, click here

Environmental Patrols

We conduct environmental patrols at each branch's construction sites to prevent air pollution, water contamination, soil contamination, noise, vibration, ground subsidence, foul odors, and other forms of environmental pollution, and to achieve zero legal violations related to the environment.

Compliance with Environmental Laws and Regulations

In order to conduct business activities with due consideration for the environment in all aspects, such as preventing global warming and ensuring proper waste disposal, we regularly monitor compliance with environmental laws and regulations. We respond promptly to any revisions of these laws and regulations and strive to prevent legal violations related to the environment. There were zero major legal violations related to the environment in FY 3/25.

Education and Awareness

Specialized Environmental Training

We provide specialized environmental training to keep all employees apprised of the necessary knowledge of overall environmental management at construction sites and the key points of legal revisions. Specialized environmental training is held annually at each headquarters and branch office, in which our employees participate regularly (once every three years). The number of participants in specialized environment training in FY 3/25 was 677.

Environmental Study Session Before Construction Commencement

To confirm and enhance the environmental knowledge of site staff, the Safety, Quality and Environment Management Division conducts environmental study sessions prior to the start of construction. Through this training, we ensure thorough implementation of measures to prevent environmental contamination and to maintain compliance with laws and regulations. In FY 3/25, sessions were held at 141 sites.

Metrics and Targets

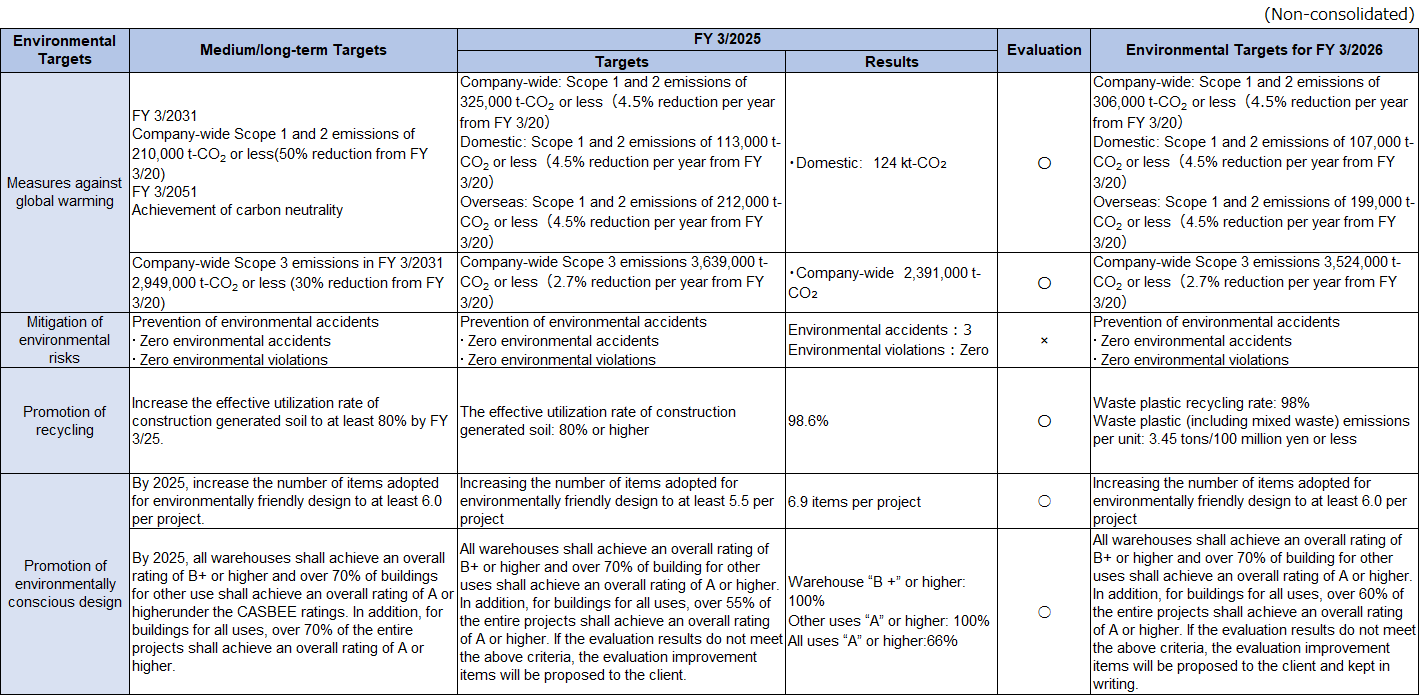

Environmental Targets and Performance

Based on our "Environmental Policy," we set annual "company-wide environmental targets" based on past activity results and annual business plans, and develop environmental activities to achieve these targets.

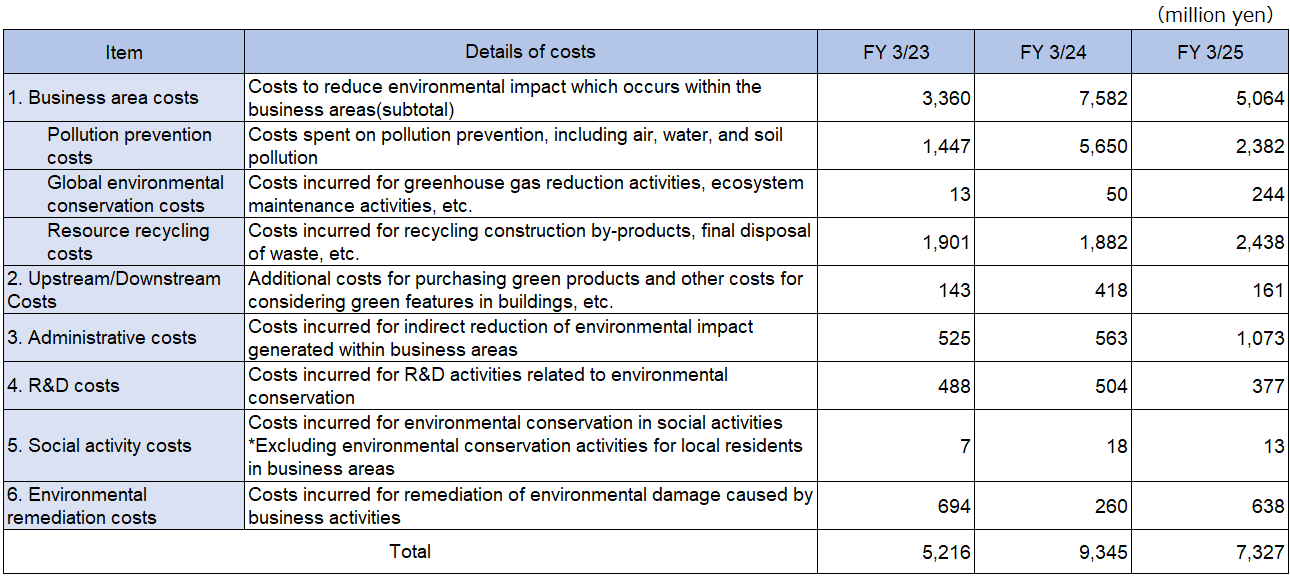

Environmental Preservation Costs

Since FY2000, we have been disclosing our environmental preservation costs as an effective means of disclosing accurate information on the status of our environmental preservation initiatives to ensure the efficient implementation of environmental preservation activities and to make the most of our environmental management.

Environmental preservation costs are affected by factors such as an increase in construction projects aimed at reducing environmental impacts and the expansion of global warming prevention measures.

Basic Items and Calculation Method

The environmental conservation costs are calculated according to our calculation standards based on the "Environmental Accounting Guidelines for the Construction Industry 2002" (published by the three associations: Japan Federation of Construction Contractors, Japan Road Contractors Association and Japan Dredging and Reclamation Engineering Association) and the "Environmental Accounting Guidelines 2005" (published by Ministry of the Environment).

- Business area costs are calculated based on costs incurred at work sites only.

- Upstream/Downstream costs, R&D costs, and social activity costs are calculated only for costs incurred in indirect divisions groups, such as headquarters and branch offices.

- Management activity costs and environmental damage costs are calculated as the sum of costs incurred at work sites and indirect divisions groups.

- Costs for work sites are estimated based on the figures from the sample sites excluding overseas projects and the amount of work completed during the period.

- Indirect costs were calculated for all headquarter offices and branch offices (including sales offices), excluding those incurred in overseas offices.

- The number of work sites sampled was 39 for civil engineering projects and 12 for building construction projects, for a total of 51.

*Figures are rounded to the nearest number.