This Page is Home![]() Sustainability

Sustainability![]() Environment

Environment![]() Resource Recycling

Resource Recycling

Resource Recycling

Penta-Ocean Construction Group utilizes construction-generated soil, dredged soil, waste, and other materials generated during construction as resources, commercializes their cyclical use and creation of added value, and contributes to the formation of a recycling-oriented society. At construction sites, we have been promoting zero-emission activities company-wide since fiscal 2006 to reduce final disposal volumes, and are implementing 3R (Reduce, Reuse, Recycle) promotion activities with full participation, based on the principle of suppressing generation.

Effective Use of Soft Dredged Soil

Calcia Reforming Technology

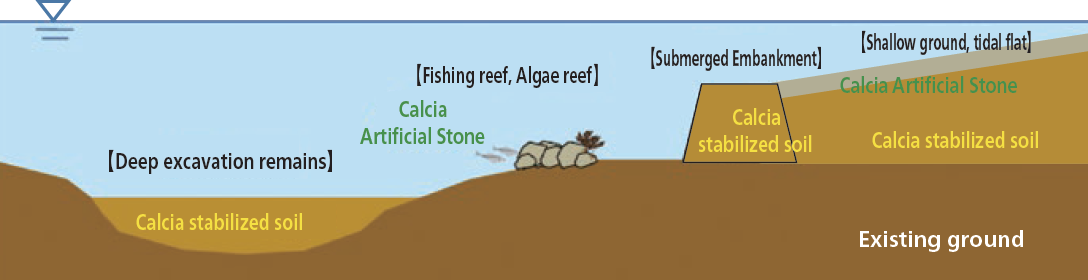

Calcia stabilizing technology is a technology that improves the physical and chemical properties of soft dredged soil generated in ports by mixing it with Calcia stabilizing material (a material made by controlling the composition and adjusting the particle size of converter steelmaking slag generated in the steelmaking process).

The Calcia reformed soil made by the Calcia reforming technology can be widely applied in marine constructions such as landfill material, partition embankment material, revetment backfill material, and marine embankment material for repairing route burial. It is expected to shorten the construction period and reduce costs.

Our company has long focused on Calcia stabilizing technology as an effective method for utilizing dredged soil and by the end of fiscal 2024 used it to create over 2 million m3 of Calcia stabilized soil. We are also engaged in the development of large-scale construction technologies, the construction of Calcia stabilized soil drop mixing vessels, the development of efficient construction methods, and the creation of new materials such as advanced Calcia stabilization technologies incorporating short fibers and soil improvement agents.

Example of calcia improved soil utilization: Nagoya Port Tokai Motohama North Public Waters Reclamation Project (Japanese)

Recycling Business

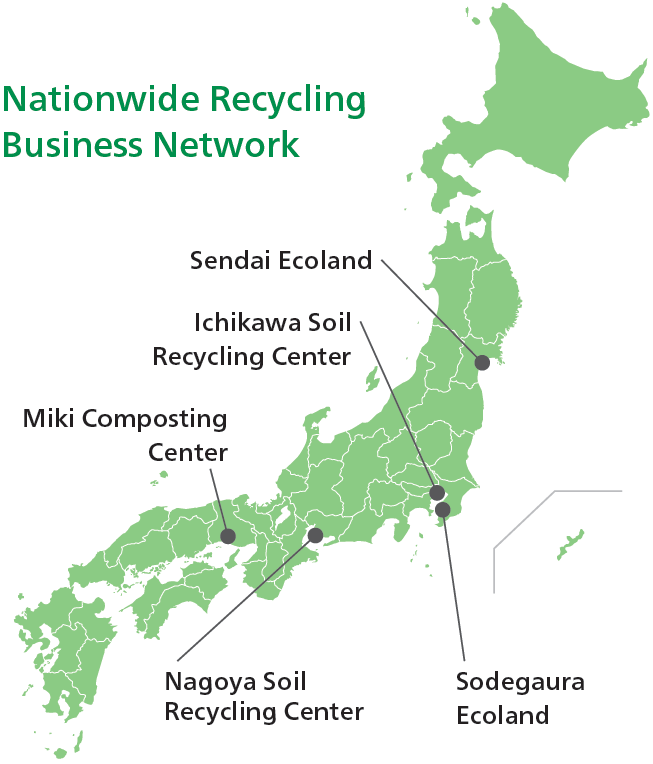

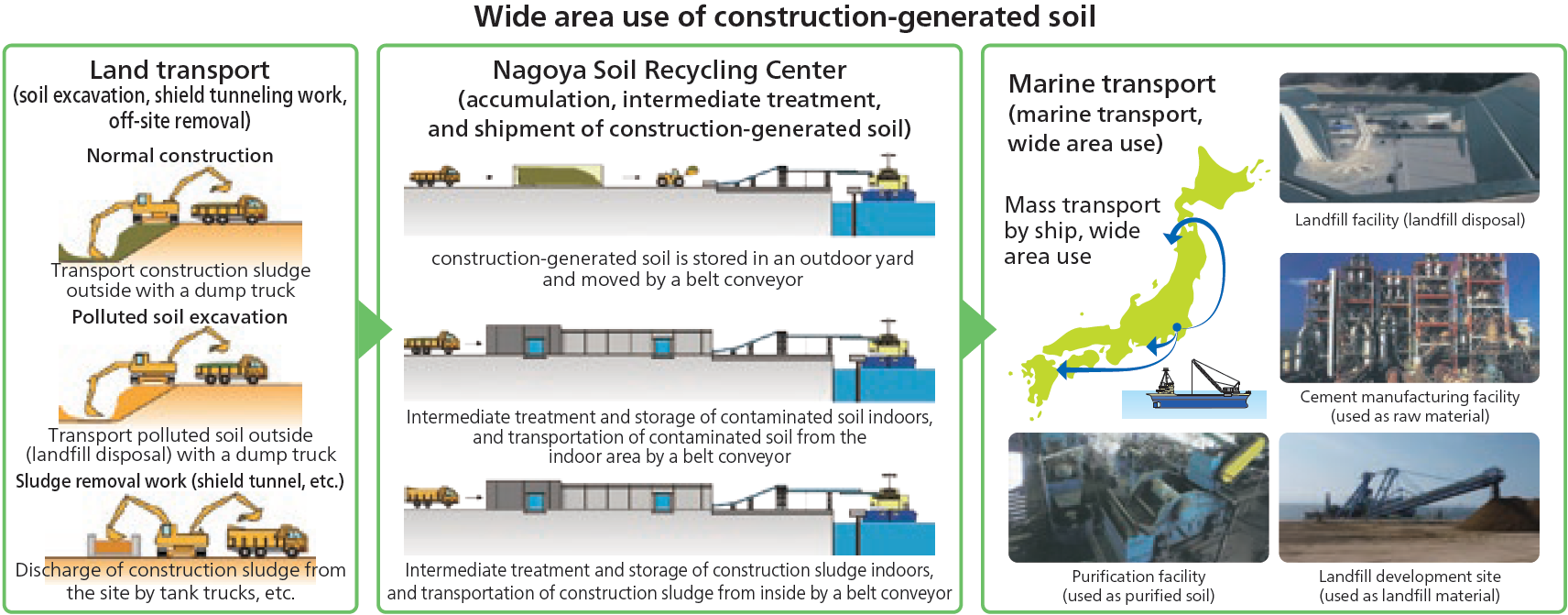

The recycling of construction-generated soil is an important issue for the construction industry. Our company is developing maritime hubs and building a wide-area network to promote the utilization of soil as a resource. In addition, we are collaborating with the steel industry to develop new environmentally conscious technologies (Calcia reforming technologies) for the use of dredged soil, and are working to expand the range of applications for dredged soil as construction material.

Recycling of Construction Generated Soil and Construction Sludge

In 2014, we expanded our Ichikawa office in Chiba Prefecture, which undertook marine transportation of construction soil for utilization as a reclamation material, and opened the Ichikawa Soil Recycling Center as a facility to receive construction generated soil and contaminated soil. The received contaminated soil is properly treated and then used cyclically, for example, as raw material for cement. We opened a soil recycling center in Yokohama in 2017(until 2024) and another center in Nagoya in 2018. In 2021, we began accepting construction sludge in Nagoya, and in 2022, we launched the production and sale of slurry fill in Ichikawa as part of our construction sludge recycling initiative. Through these efforts, we are advancing comprehensive initiatives for the proper treatment and wide-area recycling of excavated soil, with operational bases in both the Kanto and Chukyo regions.

Ichikawa and Nagoya Soil Recycling Centers

Business Overview

We operate Soil Recycling Centers (in Ichikawa and Nagoya) that are involved in the accumulation, intermediate treatment, and shipment of construction-generated soil in order to properly process and widely reuse construction-generated soil, contaminated soil, and construction sludge generated in the Kanto and Chubu regions.

Characteristics of the Business

- Reduction of truck transport distances by leveraging locational advantages in the Kanto and Chubu regions

- 24-hour system for accepting soil and sand

- Mass transportation of soil and sand using wharves that can accommodate large vessels

High cost competitiveness for transporting large volumes of generated soil in urban areas

Ichikawa Soil Recycling Center

(Contaminated soil treatment business permit: No. 0781001004)

Nagoya Soil Recycling Center

(Contaminated soil treatment business permit: No. 10900010002,

Industrial waste disposal division of labor: Permission No. 064200622304)

* Recycling of construction generated soil and construction sludge is handled by Sand Techno Co., Ltd. (Japanese) (a wholly owned consolidated subsidiary)

Sendai Ecoland

Business Overview

We improve (granulate and solidify) inorganic sludge* generated from construction and excavation work, and recycle it as construction material "Simarussa" (recycled sand).

* Sludge that cannot be used as it is, such as construction sludge mixed with cement or bentonite or with a high water content ratio.

Characteristics of the Business

- Granulation and solidification of high water content construction sludge can be performed in a few minutes

- No need for pre-treatment such as dewatering or drying during granulation and solidification of construction sludge

- No water pollution, noise, vibration, or dust

- "Simarussa" (recycled sand) has sufficient strength to be used as a material for civil engineering

* Granulation and solidification of high water content construction sludge is handled by JAIWAT Co., Ltd. (Japanese) (a wholly owned consolidated subsidiary)

Paper Sludge Incineration Ash Recycling Business Water-absorbing Mud Stabilization Material "Watoru"

Sodegaura Ecoland

The water-absorbing mud stabilization material "Watoru" is a hydration-treated product made by mixing a special chemical with incinerated paper ash (PS ash) from paper manufacturing sludge generated by paper factories. In addition to having physical reforming through water-absorption (with an instantaneous reforming effect), it demonstrates chemical reforming ability as time advances (with gradual strength development). The material received the Excellent Award in the Infrastructure Technology Development Award in 2021 and is highly recognized as an effective recycling material.

* " Watoru " is a product of JAIWAT Co., Ltd. (Japanese), POC's wholly owned consolidated subsidiary, and is produced in a JAIWAT's manufacturing plant named "Sodegaura Eco-land" located in Sodegaura city, Chiba Prefecture. JAIWAT handles everything related to Watoru, from material procurement to manufacturing, distribution, and quality control.

Food Recycling Business

This business processes and sells compost materials made from organic waste discharged from food-related companies, etc.

Miki Composting Center

Characteristics of the Business

- With the automatic agitator (scoop-type) and the forced air circulation (aeration), collected food waste is subject to primary fermentation for about 1 month, and then further fermentation and maturation for about 3 months to produce complete compost.

- Since the Miki Composting Center is located near the Hanshin district with concentration of many food-related companies and easily accessible from interchanges of the expressway, it contributes to the reduction of waste transport costs.

- In addition to selling compost, the center also provides compost spreading services, contributing to the improvement of soil fertility in Japan's farmlands.

Use of Recycled Product (Compost "Minami-No-Hikari")

- Because it is made from food waste, it is a safe and nature-friendly organic compost.

- Fully meets the quality standards of the NPO Japan Bark Compost Association, surpassing common composts. It can be used in various situations from full-scale agriculture to landscaping/greening projects and kitchen gardens.

- The performance of our recycled products has been evaluated, and our product delivery record is improving.

* Food waste recycling is handled by Miki Biotech Co., Ltd. (Japanese) (a wholly owned consolidated subsidiary) at the Miki Composting Center in Miki City, Hyogo Prefecture.

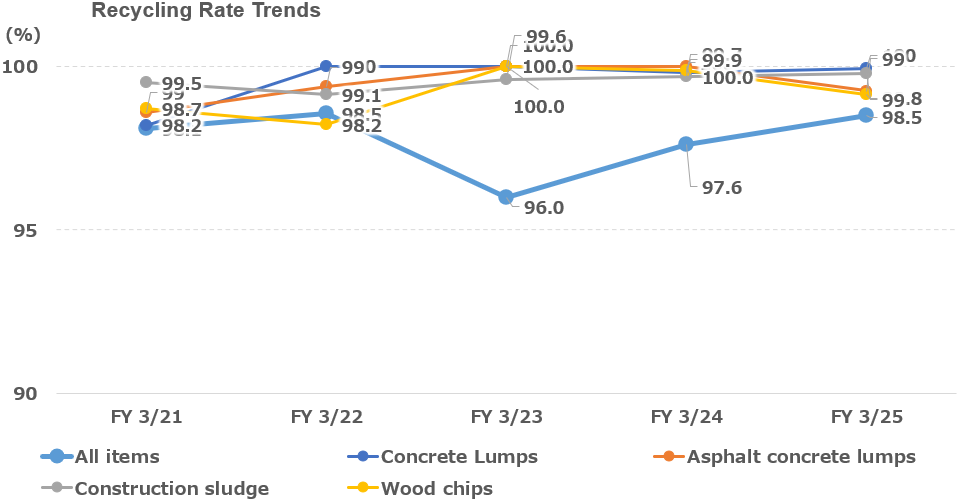

Zero Emission Promotion Activities

We define zero emissions as the reduction of the final disposal volume of construction by-products to as close to zero as possible and have been promoting this initiative company-wide domestically since FY 3/07. POC's overall recycle rate of construction waste for FY 3/25 was 98.5% (97.6% for the previous year) and the final disposal rate was 1.5% (2.4% for the previous year), with the basic unit of final disposal of waste per construction volume at 2,007 kg/100 million yen (FY 3/24 Performance: 3,334 kg/100 million yen). In FY 3/26, we will strive to improve the recycling rate and make systematic efforts to achieve zero final disposal of waste.

Basic Policy for Promoting Zero Emission

Promote the 3R activities and strive to achieve zero final disposal volume in construction waste

Priority Items

- Reduction of construction waste generation

- Ensuring sorted waste collection and waste recycling in line with regional characteristics

- Conducting educational and awareness-raising activities (sharing awareness)

Metrics and Targets

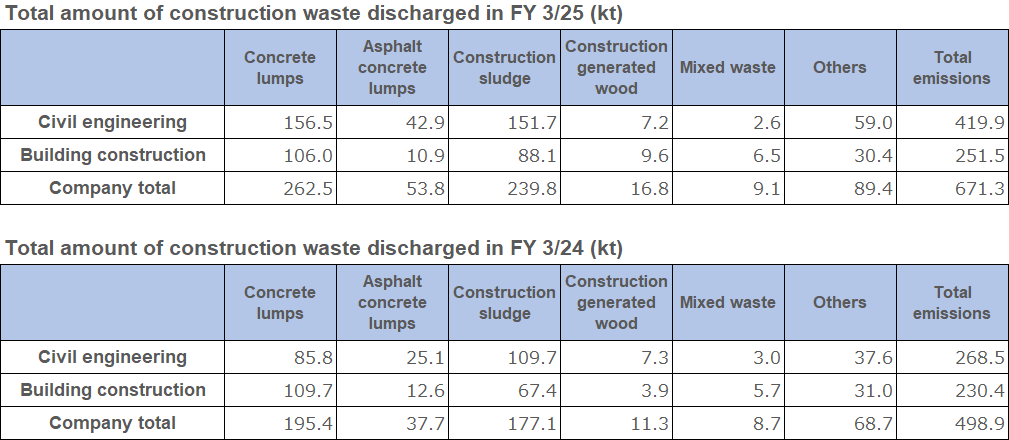

Amount of Construction Waste

Total emissions for FY3/25 increased by 172.4 thousand tons from the previous year to 671.3 thousand tons. The increase in concrete debris and construction sludge in civil engineering projects has had an impact. On the other hand, waste emissions per unit of production decreased by 16.6 t/100 million yen to 101.6 t/100 million yen, showing a downward trend in both civil engineering projects and building construction project.

Recycling Rate

In FY 3/25, the overall recycling rate for all items increased by 4.4% to 98.7% for civil engineering projects, increased 20% to 98.4% for building construction projects, resulting in an overall rate increased by 3.5% to 98.5%, from FY 3/24 (FY 3/24 result: 97.6%). In addition, the final disposal rate was 1.5% (FY 3/24 result: 2.4%), and the basic unit of final waste disposal per construction volume was 2,007 kg/100 million yen (FY 3/24 result:3,334 kg/100 million yen).

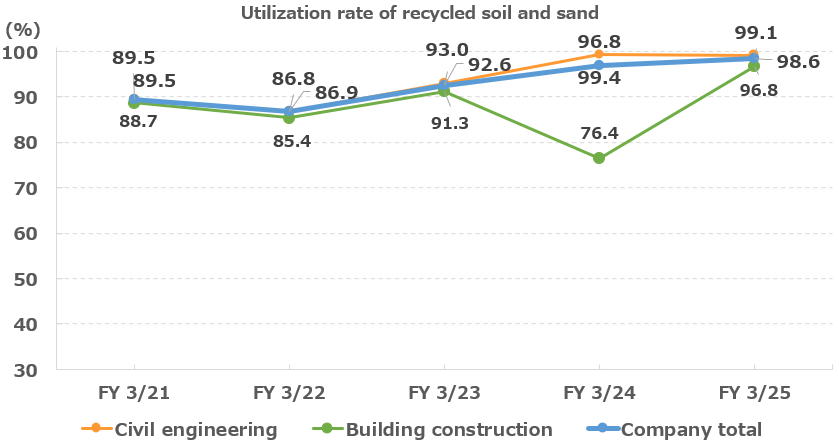

Effective Utilization Rate of Construction Generated Soil

The company-wide effective utilization rate of construction generated soil in FY 3/25 was 98.6% (FY 3/24 result: 96.8%), an increase from the previous fiscal year. We will continue to work on improving these utilization rates in FY 3/26 and beyond.

Promotion of Energy and Resource Saving in Offices

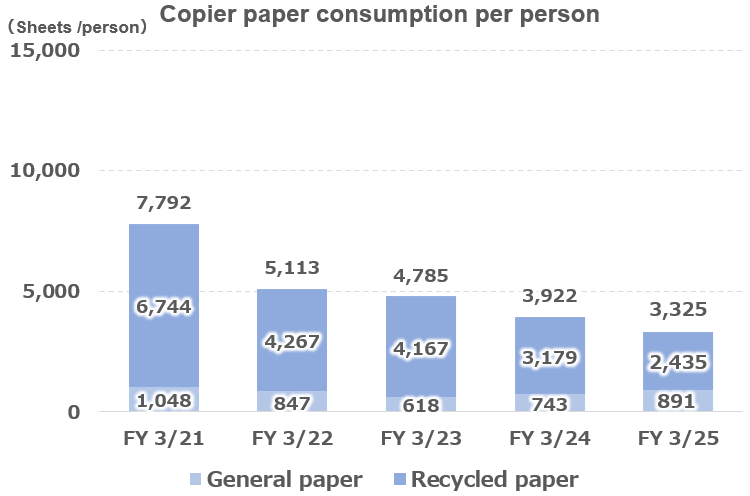

As part of our efforts to conserve resources and energy in our offices, we are working to reduce the amount of copier paper used, conduct green procurement, reduce electricity consumption, and sort and collect waste.

Reduction in Consumption of Copier Paper

We are thoroughly implementing activities to reduce copy paper usage through double-sided copying, one-sheet copying, use of the reverse side, use of electronic media, use of recycled paper, and inventory control of purchased quantities.

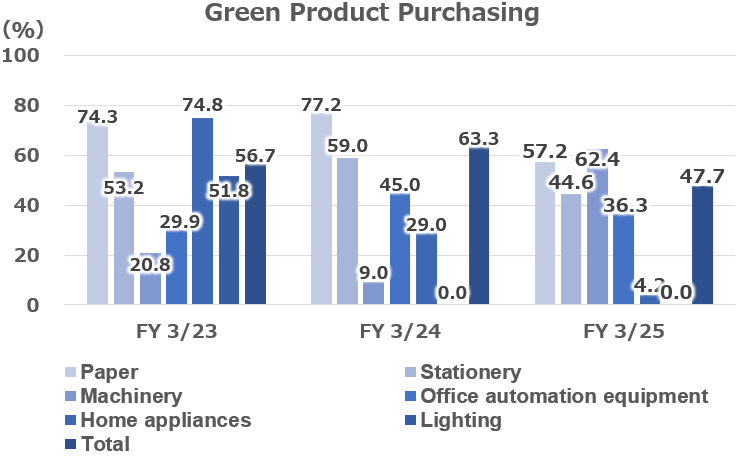

Green Purchases

As part of our office environmental activities, we manage the ratio of green product purchases for office supplies. We will continue to promote green purchasing.

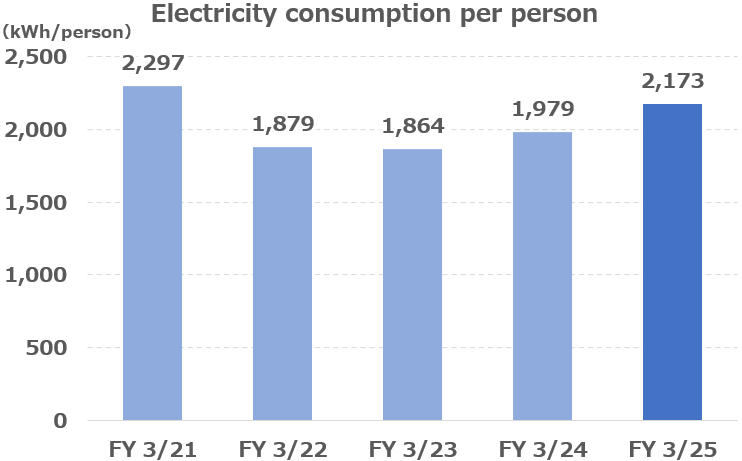

Reduction of Electricity Use

We are working to reduce electricity consumption by implementing power-saving measures such as turning off lights during lunch breaks, turning off partial lights when leaving the office, setting air conditioner temperatures and operating air conditioners in limited areas after hours, and using electric fans.

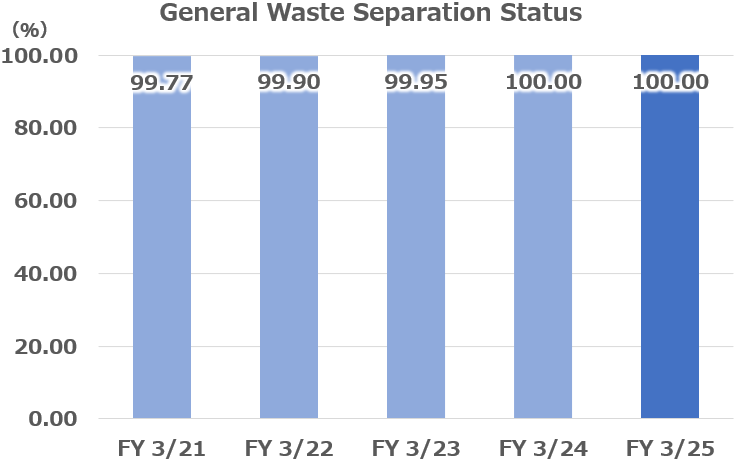

Separate Collection of Waste

Separate trash boxes are placed on each floor of the office for separate collection.