This Page is Home![]() Updates

Updates

What's New

Penta-Ocean Construction Co., Ltd.

Takuzo Shimizu, President, CEO and Representative Director

Development of the “Curved Drilling AI Guidance System” to Promote Inheritance of Technological Expertise

Tokyo, Japan - Jan. 16, 2026 -In reference to the “Curved Drilling Permeation Grouting Method”, a liquefaction countermeasure technique used directly beneath existing structures, Penta-Ocean Construction Co., Ltd. (President Takuzo Shimizu) and Raito Kogyo Co., Ltd. (President Kazuhiro Akutsu) have jointly developed a new AI-based drilling operation support technology , the “Curved Drilling AI Guidance System,” and verified its operational effectiveness through field demonstration tests. The system enables less-skilled operators to improve drilling accuracy by approximately 55% and reduce drilling time by approximately 20%, achieving construction quality comparable to highly experienced operators.

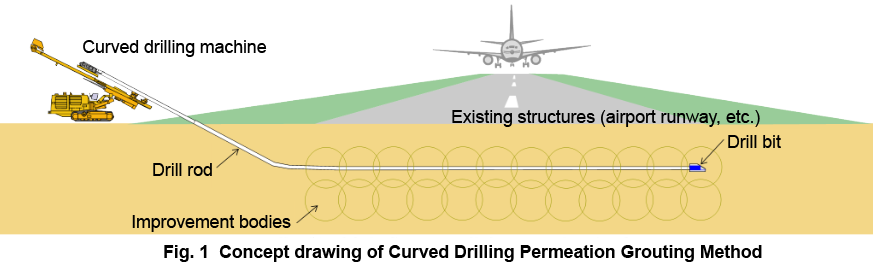

The curved drilling method is employed as an effective liquefaction countermeasure directly beneath existing critical structures, including airport runways and major buildings, owing to its capability to drill along curved paths under the ground (Fig. 1). However, drilling along the designed alignment required a high level of skill, resulting in the challenge that only highly experienced operators could carry out the drilling as planned.

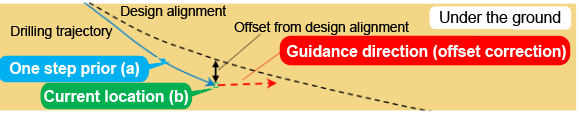

The newly developed Guidance System supports the drilling operation performed by less-skilled operators and consists of two analytical programs arranged in a two-phase structure (Fig. 2). The first program, a real-time position estimation program, employs deep-learning models, an AI technology. It performs real-time estimation of the current borehole position (position [b] of Fig. 2) using the position data and operator’s control data (such as the drilling-bit angle and tilt angle of drilling rod, etc.) obtained in the previous step (position [a] of Fig. 2). The System has been trained using drilling data accumulated over a 2,000-m length, enabling highly accurate estimations. The second program, an optimal control input estimation program, incorporates the offset between the current position and the design alignment and the operator’s control inputs in order to calculate the optimal control input required to steer the drilling trajectory back toward the design alignment. By repeatedly executing the first and second programs, the System provides continuous guidance throughout the entire drilling length.

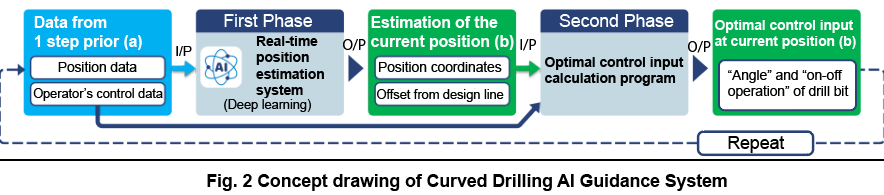

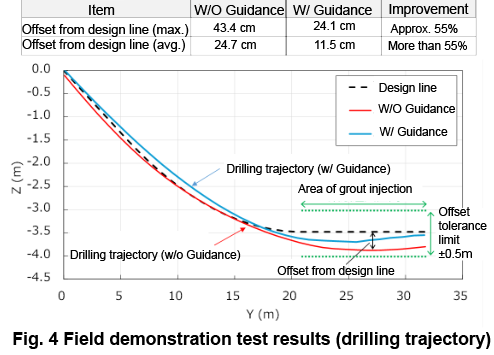

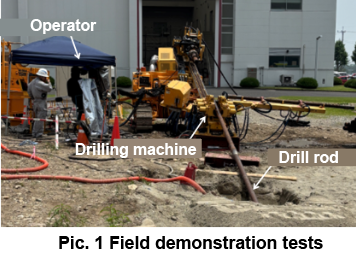

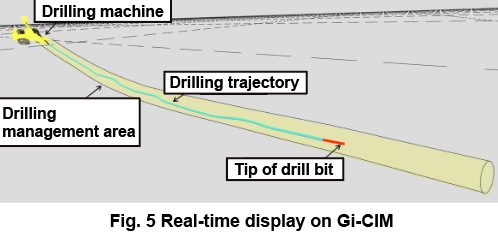

During the field demonstration tests, inexperienced operators conducted a 32 m of curved drilling operation, comparable to actual construction, to verify the System’s effectiveness (Fig. 3, Pic. 1). Without this guidance, the offset of the drilling trajectory came close to the tolerance limit. With the System’s assistance, the maximum offset was reduced by approximately 55 %, thereby achieving a significantly high level of drilling precision (Fig. 4). In addition, the real-time calculation and display of the optimal control enhanced operators’ decision-making process and reduced drilling time by approximately 22 %. Furthermore, integration of the 3D visualization tool “Gi-CIM” developed by Penta-Ocean Construction, enabled remote, real-time monitoring of the progress of drilling activity, greatly improving the efficiency of finished-shape quality verification (Fig. 5).

Both companies will continue to collect additional drilling data and advance AI learning to further improve the position-estimation accuracy that underpins the System’s guidance, thereby contributing to improved construction productivity and enhanced quality assurance. Moreover, by enabling the “Digital inheritance of expertise”, the System will help address one of the construction industry’s most critical issues: the rapid decrease in skilled workers.