This Page is Home![]() Updates

Updates

What's New

Penta-Ocean Construction Co., Ltd.

Takuzo Shimizu, President, CEO and Representative Director

Real-time distribution of heavy construction machinery locations and construction progress

Tokyo, Japan - August 23, 2022 - Penta-Ocean Construction, in collaboration with Applied Technology Co., Ltd. and SOFTBANK Corporation, established a technology to project the position of heavy construction machinery onto a BIM model in real time. This technology has been implemented in the Penta-Ocean integrated Construction Management System (PiCOMS). We conducted a demonstration test to apply the technology to the site of a large-scale logistics facility construction project, and confirmed its successful contribution to the productivity improvement.

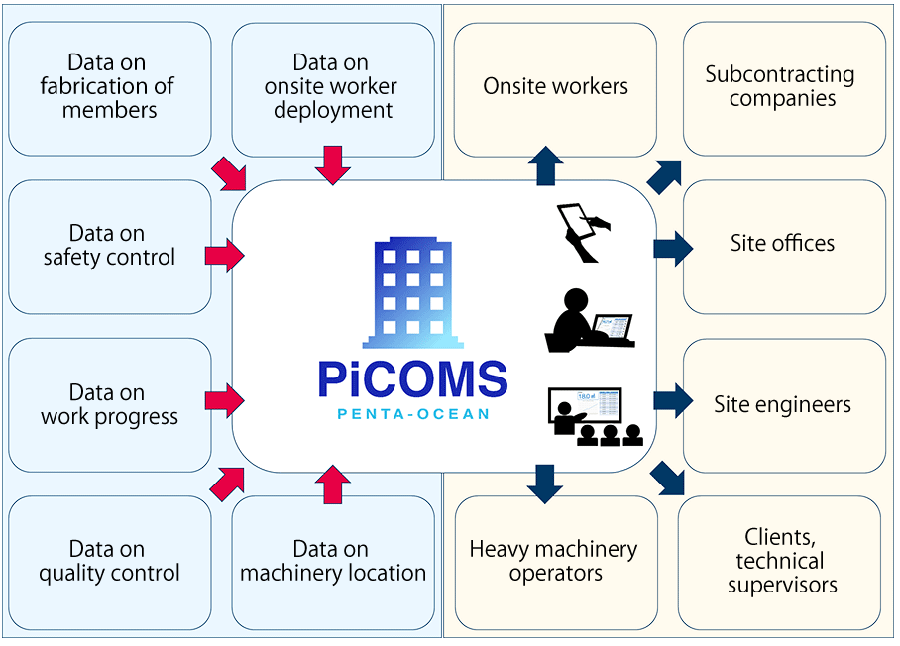

We developed PiCOMS in a bid to improve productivity in construction management and to enhance Work Style Reform. The system allows for visualization of the progress of construction work, centralization of various data sets including work progress, quality/safety control and on-site deployment of workers, followed by real-time sharing of the data amongst related parties. We have been proactively promoting its implementation at construction sites (Figure 1).

In conventional construction management for earthwork and pile driving work which employ heavy construction machinery, it was the site engineer’s routine procedure to foot patrol the site to monitor the operating status of heavy machinery and jot down the results on a site layout map. At large-scale construction sites on an extensive area of land with many pieces of heavy construction machinery, these tasks were time-consuming and labor intensive.

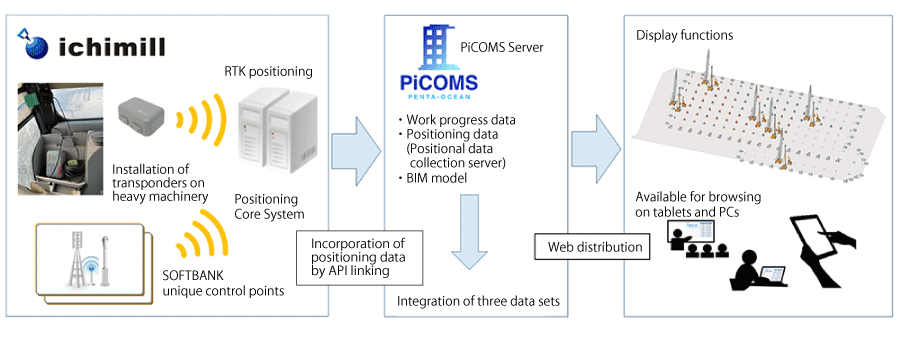

This new technology employs a high-precision positioning (RTK positioning) to pinpoint location of heavy machinery. By linking the positional data server, which contains the collected positional data of machinery, to the PiCOMS server, the real-time positional data of each piece of machinery and the construction progress are combined and integrated into and visualized on the BIM model. The visualized data becomes available for display, whether on large PC screens in site offices and workers’ rest areas, or on their own tablet terminals (Figure 2). The system also has a capacity to keep track of the operating hours of machinery, allowing for collection of data on location and operating hours of heavy machinery during the entire construction period.

In the verification test of pile driving work at a site operating up to 20 pieces of heavy machinery (Figure 3), we confirmed that the onsite workload was reduced to the one-fifth level compared to the conventional procedures, by automating tasks for information sharing among the related parties and by organizing meetings premised on real-time onsite data.

The data will be continuously accumulated and analyzed to develop more effective construction plans that incorporate heavy machinery deployment plans and their operating conditions. In the regard that this will lead to further productivity enhancement, we plan to proactively promote implementation of the technology across our construction sites. In addition, we will work on "Visualization of onsite CO2 emissions" by automatically calculating CO2 emissions from heavy machinery based on actual operating hours.