This Page is Home![]() Updates

Updates

What's New

Penta-Ocean Construction Co., Ltd.

Takuzo Shimizu, President, CEO and Representative Director

“ZEB Conversion of Factory and Use of Hydrogen Energy” (Construction of the New Muroran Factory)

Tokyo, Japan - Nov. 10, 2021- Penta-Ocean Construction Co., Ltd., upon construction of a new plant for its Muroran Factory (Muroran City, Hokkaido), which manufactures steel structures for bridges, etc., will convert not only the offices but also the entire factory into a net Zero Energy Building (ZEB), and hydrogen energy will be used and demonstrated as a renewable energy source.

We have been involved in the planning, construction, and verification of ZEB buildings in actual properties, including the acquisition of a ZEB certification for the Hisamitsu Museum in 2019 and a Nearly ZEB certification for the Kyowa Exeo Minami Kanto Branch in 2020. In addition, we conducted demonstration tests of energy-saving technologies using five elements (water, air, heat, electricity, and control) at the laboratory building of our Institute of Technology, and have achieved an energy-saving rate of 72% not including energy creation.

Considering that the new factory will be located in a cold region, we will enhance the energy saving by using various technologies including; 1) improving thermal insulation by using resin sashes, 2) reducing the lighting load by diffusing daylight through window films, 3) introducing high-efficiency air-conditioning apparatus tailored for cold regions, and 4) installing human sensor control for automatic operation of the above apparatus. This will result in 62% reduction rate of energy saving of the offices.

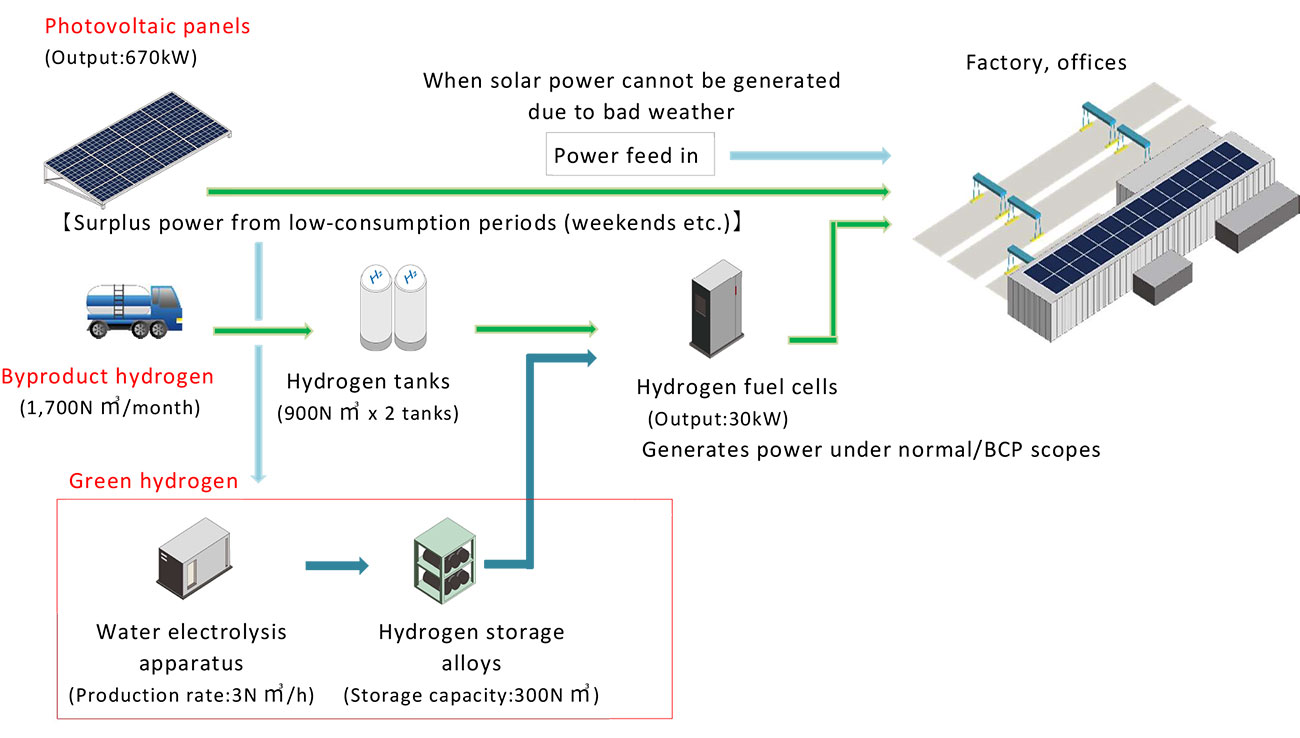

As for the energy creation, we will install a photovoltaic power generation system (output: 670kW)and fuel cells (output: 30kw) on the roof of the factory, and the entire factory will be converted to ZEB by using green power to supply not only for the offices but also for the whole factory, from a single electric light to necessary power for the factory operation.

For the utilization and demonstration of hydrogen energy, we will use (1) byproduct hydrogen and (2) green hydrogen produced from surplus solar power generation. The byproduct hydrogen will be stored in tanks (900Nm3 x 2 tanks) and used constantly in the offices through power generation by fuel cells

.

Green hydrogen, on the other hand, is produced by water electrolysis apparatus (production rate: 3Nm3/h) using surplus electricity from solar power generation, and stored in hydrogen storage alloys (storage capacity: 300Nm3) to generate power using fuel cells as needed or when Business Continuity Plan (BCP) measures are in place.

To achieve carbon neutrality, we are constantly taking on green field challenges, such as the construction of offshore wind power generation facilities and the conversion of conventional buildings to ZEB. As a result of this initiative, we will gain extensive expertise on ZEB conversion of buildings and factories as well as hydrogen energy utilization. Therefore, we hope to see the Muroran Factory play a more prominent role as a green manufacturing hub for temporary steel structures related to offshore wind power construction, which are expected to be in high demand in the future, in addition to its original focus on bridge steel structures. Muroran City is known to have been actively promoting carbon-neutral initiatives such as proliferating the use of hydrogen, attracting businesses related to offshore wind power generation, and making the Port of Muroran a base port, through the activities of “The Muroran City Council for Decarbonization” and “The Muroran Offshore Wind Industry Promotion Association (MOPA)”, in which we also participate. We will continue to promote carbon-neutral initiatives in Muroran, which was the point of entry for our full-scale expansion into Hokkaido back in 1970.