This Page is Home![]() Updates

Updates

What's New

Penta-Ocean Construction Co., Ltd.

Kanmon Kowan Construction Co., Ltd.

Construction of “Ocean 3”, a Calcia Improved Soil Drop Mixing Vessel, Capable of Large-Scale Work using Calcia Improved Soil

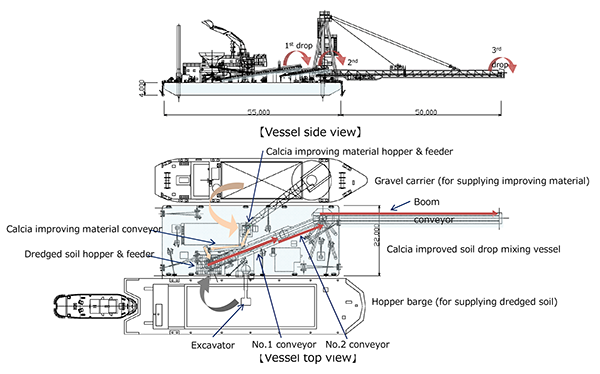

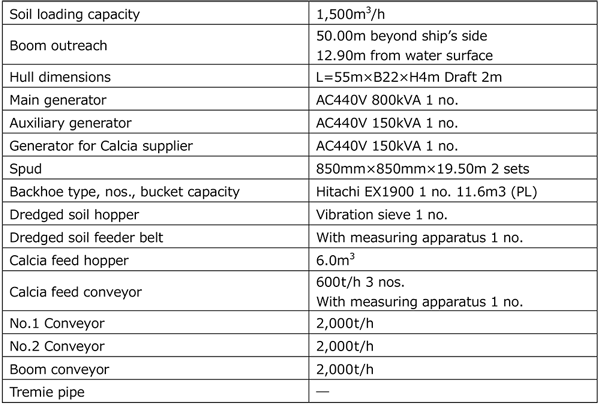

Tokyo, Japan - June 22, 2021- Penta-Ocean Construction Co., Ltd. (President: Takuzo Shimizu) and Kanmon Kowan Construction Co., Ltd. (President: Seiro Kiyohara) have jointly built the "Ocean 3", a Calcia improved soil drop mixing vessel that can efficiently produce large quantities of Calcia improved soil by mixing dredged soil with Calcia improving material( made of steelmaking slag processed by component management and particle size adjustment ). The Ocean 3 is a reclaimer vessel (a work ship that uses conveyor belt to transport dredged soil etc. to a landfill site), specially equipped with a feed hopper for Calcia improving material, a feed conveyor, and a mixing and casting conveyor.

There are several methods for mixing dredged soil with Calcia improving material; backhoe mixing method, pneumatic flow mixing method, and drop mixing method. After numerous tests using dredged soil of different soil properties, it has been proven that drop mixing method, which is mainly adopted by a reclaimer vessel, is capable to produce high-quality and homogeneous Calcia improved soil by dropping the soil three times from the height of 2m or more above the ground. However, the use of a reclaimer vessel for the above purpose requires outfitting of special apparatus, such as a feed hopper for Calcia improving material and feed conveyor. In addition, given that a reclaimer vessel allows only two dropping attempts at the time of conveyor belt transfer and casting into the water, it was necessary to add one more drop operation outside the vessel, either during transshipment ashore or during unloading of soil after transport by lifting the cargo bed of the dump truck.

The new vessel allows for a total of three attempts of drop mixing: twice during the transfer of the conveyor belts and once during the drop from the boom conveyor.

Furthermore, the new vessel is equipped with a quality control system that allows real-time monitoring of the mixing ratio of the Calcia improving material, the density and water content ratio of the Calcia improved soil, which conventionally could have been monitored only through sampling inspections. This has made it possible to produce a high-quality Calcia improved soil with the accurate composition.

Together with Kanmon Kowan Construction Co., Ltd., we will utilize the Ocean 3 to efficiently promote the use of Calcia improved soil for reclamation and backfilling of deep excavation sites, as well as creation of shallow areas and tidal flats.

- Enables large-scale operation

Capable of producing from 2,500 to 4,000 m3/day of Calcia improved soil - Improves operation efficiency

No outfitting is required, resulting in shorter construction period

No need for mixing work outside the vessel, as three drops for mixing are assured by the time of soil discharge from the vessel

Direct underwater discharge using tremie pipe enables the creation of shallows and tidal flats as well as backfilling of deep excavations - Contributes to quality assurance and improvement

Real-time confirmation of the mixing ratio of the improving material, the density of Calcia improved soil and the water content

Quick response to excessive or insufficient amount of the improving material to produce the high-quality improved soil