This Page is Home![]() Updates

Updates

What's New

Penta-Ocean Construction Co., Ltd.

The 21 General Contractors take “Joint Research and Development of Bar Arrangement Inspection System” to the Next Stage

-Bar Arrangement Inspection System begins on-site trials -

Tokyo, Japan – Dec. 15, 2020 – Since April 2019, the 21 General Contractors have been conducting joint research and development (R&D) of “Bar Arrangement Inspection System”, applying AI and image analysis in order to improve the productivity at construction sites. The goal of the R&D is to develop an integrated system with two functions: the "Bar Arrangement Checking Function” to support the construction management of reinforcement work and the "Bar Arrangement Inspection Function" to improve the efficiency of the reinforcement inspection.

As a result of on-site trials of the “Bar Arrangement Checking Function” using tablet terminals, we have reached a certain level of success in checking reinforcement arrangement rapidly and accurately in different construction environments. In these on-site trials, it was found that efficient development could be achieved by sharing the objectives of system improvement on the basis of each participant company’s AI analysis of the reinforcement arrangement images. We will continue to conduct on-site trials with the aim of developing more versatile functions.

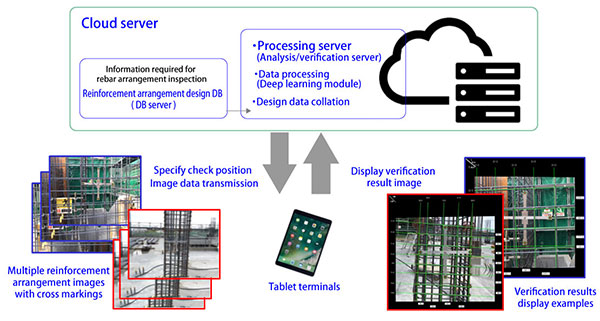

In order to prevent the spread of the new coronavirus infection and to ensure construction quality while avoiding human contact, the members of the general contractors are required to share construction information efficiently and confirm it at every stage. The 21 general contractors participating in the joint R&D are responding to rapid changes in society by sharing and collaborating on technologies and expertise accumulated by each company. The following is a schematic diagram of the “Bar Arrangement Checking Function" and an example of the verification results.

Schematic diagram of the “Bar Arrangement Checking Function and

Schematic diagram of the “Bar Arrangement Checking Function and examples of the verification results

1.Overview of the “Bar Arrangement Checking Function”

During the on-site trials, after the check position is specified by the tablet terminal, the cross marker is set at the center of the image, multiple reinforcement photographs are taken and the photo data is sent to the processing server. Using deep learning technology and image procession within the server, the diameter, number of reinforcing bars, pitch, etc. of the reinforcement are calculated. The calculation result is checked with the design and an error verification is made on the basis of the preset control value.

The verifier checks the result of the computation shown on the reinforcement photograph with the calculated value on the tablet terminal and visually re-checks the reinforcing bar indicated by the system. This contributes to the prevention of human error by double-checking at both human eye and system levels.

2.Features

Since the “Bar Arrangement Checking Function” is processed by the deep learning module implemented in the cloud server, the verifier only needs a cross marker and a tablet terminal to use this function. Consequently, reinforcement checking can be performed immediately after setting work, preventing oversight of inspection or rework after the inspection.

In addition, the deep learning module is stored in the server, so additional learning of reinforcement arrangement and version upgrade of the learning module can be easily performed during system operation.

3.Future development

The participant companies will continue to improve and enhance the system by conducting further on-site trials and analyzing the verification results. Furthermore, by reflecting each company’s different verification results and improving system performance by upgrading the learning module, we will expand the scope of use in order to respond to different construction situations.

We also plan to start implementing the "Bar Arrangement Inspection Function" at construction sites early next year.

21 participating companies in the R&D (in Japanese alphabetical order)

Asunaro Aoki Construction Co.,Ltd., Asanuma Corporation,

Hazama Ando Corporation, Okumura Corporation,

Kitano Construction Corporation Kumagai Gumi Co., Ltd.,

Penta-Ocean Construction Co., Ltd., Sato Kogyo Co., Ltd.,

Daisue Construction Co., Ltd., Takamatsu Construction Co., Ltd.,

Tekken Corporation, Tokyu Construction Co., Ltd.,

Toda Corporation, Tobishima Corporation, Nishimatsu Construction Co., Ltd.,

JDC Corporation, Haseko Corporation, P.S. Mitsubishi Construction Co., Ltd.,

MATSUMURA-GUMI Corporation, MURAMOTO Corporation, Yahagi Construction Co., Ltd.