This Page is Home![]() Updates

Updates

What's New

Penta-Ocean Construction Co., Ltd.

Obtained structural performance evaluation of "Design and construction method of reinforced concrete beam using various casting techniques with different concrete strengths"

Tokyo, Japan – June. 17, 2020 – The six general construction companies (Asanuma Corporation, Okumura Corporation, Kumagai Gumi Co., Ltd., Penta-Ocean Construction Co., Ltd., Tekken Corporation and Yahagi Construction Co., Ltd.) jointly developed "Design and construction method of reinforced concrete beam using various casting techniques with different concrete strengths", and have received a structural performance evaluation from Japan ERI Co., Ltd.

This new method which obtained the performance evaluation is related to the design and construction of a beam using concrete with different strengths in the upper and lower sections. By adopting this method, it has become possible to cast the concrete of the upper section of the beam and slab with same concrete strength for cast-in-situ or semi-precast members.

In the future, we plan to apply the method to RC buildings, mainly for design and construction projects at each company to streamline the construction and improve productivity.

1.Development Background

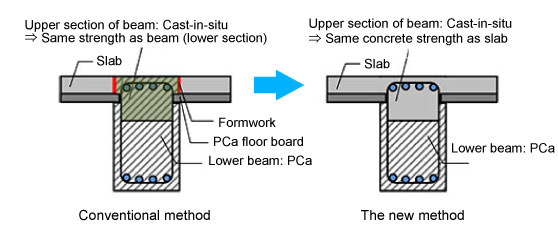

In the case of precast concrete beams of reinforced concrete structure (hereinafter referred to as RC), the lower section of the beam is precast (PCa) and the upper beam is a cast-in-situ concrete. When the beam and the slab have different concrete strengths, the conventional technique takes a number of steps as shown in the left figure below, and therefore, significant amount of time and labor is spent on the site.

Construction procedure

(1)Install a formwork to separate the upper sections of the beam and slab → Omittable

(2)Cast concrete on the upper beam → Omittable

(3)Remove the formwork after the concrete sufficiently hardened → Omittable

(4)Cast concrete on the upper slab → Simultaneous concrete casting at upper beam and slab

By adopting this method, it is possible to cast the upper section of the beam and slab with same concrete strength at one time. The construction procedures (1) to (3) can be omitted, and “rationalized construction and improved productivity” can be expected. When the concrete strength of the column is different from that of the beam/slab, it is necessary to separate the concrete casting at the column/beam joints using the conventional method.

2.Development structure and outline

This method was developed jointly by the six general contractors, namely, Asunuma Corporation, Okumura Corporation, Kumagai Gumi Co., Ltd., Penta-Ocean Construction Co., Ltd., Tekken Corporation and Yahagi Construction Co., Ltd.

The six general contractors brought in their respective experimental data and organized the experimental results produced by other competitors. Consequently, we constructed a database, devised a rational design method, and summarized the design and construction guidelines. We applied to Japan ERI for the examination of the design and construction guidelines, and obtained the structural performance evaluation at the end of November 2019.

3. Outline of design and construction guidelines

(1)Application scope

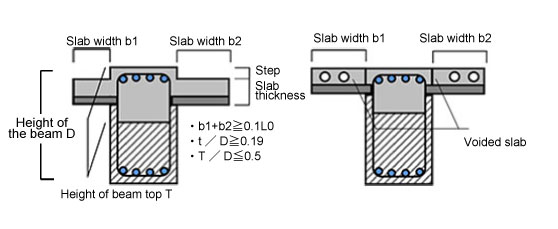

·Applicable for beams with slabs attached to one or both sides. The slab shall have a width of 0.1L0 (L0: inner span of the beam) or more, and the thickness shall be 0.19 times or more of the height of the beam.

·The height of the upper section of concrete beam (the section with weaker strength than the lower section of the beam) shall be less than half the height of the beam.

·The concrete design standard strength of the upper section of the beam shall be more than half that of the lower section of the beam.

·This method is applicable to both precast and in-situ concrete beams.

(2) Materials used

In order to differentiate from the prior techniques, we expand the classification range of reinforcement bars which can be used as main bars for the beams (SD295 – SD 490, specified by JIS G 3112), by adding the minister-approved 590N/mm2 class. Furthermore, we enabled to use the 1,275 N/mm2 class shear reinforcement, which is a minister-approved product.

The beam’s concrete design strength standard ranges from Fc24N/mm2 to Fc60N/mm2.

(3) Design method

Since concrete of different strength co-exists in the same cross section of the beam, the concept of "equivalent average strength" was introduced as the concrete strength at the time of design. Using this equivalent average strength, the team designed the allowable stress level and the ultimate strength level.

Equivalent average strength is the strength that simultaneously takes into account both the effect of slab existence and the effects of mixed concrete strength. We confirmed that the ultimate shear strength of the beam (plastic theoretical formula, Arakawa mean formula), calculated based on this equivalent average strength, can be evaluated from in-house aggregate data and the competitors’ collected data on the safety side, and they were summarized in the design guidelines.

4.Future development

Going forward, the joint research companies are planning to adopt the method in RC buildings, mainly in design and construction projects, to streamline construction and improve productivity. In addition, further improvement of this method will also be considered if necessary.