This Page is Home![]() Updates

Updates

What's New

Penta-Ocean Construction Co., Ltd.

Takuzo Shimizu, President, CEO and Representative Director

Penta-Ocean Fully Applied CIM into Construction Works in a Port for the First Time in Japan

Tokyo, Japan – March 27, 2018 – Penta-Ocean Construction Co., Ltd. (hereinafter referred to as “Penta-Ocean”) is pleased to announce that we have fully applied Construction Information Modeling / Management (CIM) into the construction works of a Liquefied Natural Gas (LNG) station in Souma port as a CIM promotion activity under Ministry of Land, Infrastructure and Transport (MLIT). It is the first time that the full-scale introduction of CIM into construction works in ports and harbours has been implemented in Japan, as shown in Diagram 1.

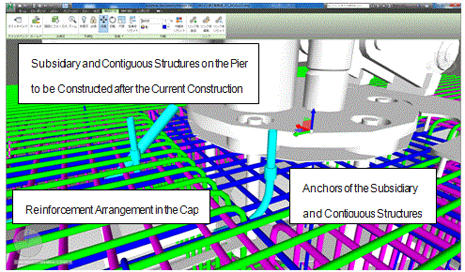

MLIT has been directing the application of CIM since 2012 by implementing a number of the trials up to the present time, and announced the CIM application guidelines in March 2017. In addition to this, the MLIT is expected to announce the CIM application guidelines in ports and harbours by the end of 2018. Amid the progress of ICT introduction, Penta-Ocean have taken initiatives to fully apply CIM into the construction of a LNG base in Souma port, whose client was Japan Petroleum Exploration Corp. Co., Ltd. (JAPEX), in order to improve productivity for the construction works in ports and harbours. The project was intended for all types of construction works for piers and their subsidiary and contiguous structures, for verifying CIM efficiency and effectiveness of the construction work performance in ports and harbours. The project is briefly described as follows:

1. Examining the construction process in chronological order

2. Finished work quality control by visualizing the bottom of the sea stratum

With CIM, it is now possible to capture the position of structures, and check the interface of pier construction materials and temporary timbering structures, before commencing the construction works. In addition, it used to be the crew members, or affiliated suppliers who respectively examined the placement plans of vessels, carry-in management of equipment and appliances, and other operation plans, which was time consuming and inefficient. In contrast, it is currently feasible to examine the construction process with 4D simulations reflecting updated data on the construction works, by integrating those plans with 3D models, and incorporating the time axis, to post all data in chronological order. Thereby, all crew members are able to share the construction plans, which helps not only improve the construction efficiency, but also increase safety awareness. In addition, CIM enables to simplify mutual understanding with construction workers.

As construction works in ports and harbours are implemented under severe environments, introduction of CIM helps not only with construction efficiency, but also maintenance management, as well as restoration work from disasters, by accumulating the data, such as the finished work quality with CIM.

Penta-Ocean will continue to work on rationalizing the construction process, with further application of CIM, and i-Construction, in order to improve the productivity at construction sites.

Diagram 1: CIM of the pier

Diagram 2: Examine the construction process with 4D simulations

Diagram 3: Calculate the embedment length of the steel-pipe pile

Diagram 4: Reinforcement arrangement in the cap, and interference check of anchors and plumbers of the subsidiary and contiguous structures