This Page is Home![]() Updates

Updates

What's New

Penta-Ocean Construction Co., Ltd.

Takuzo Shimizu, President, CEO and Representative Director

Penta-Ocean Developed “Fiber Reinforced Calcia Stabilized Soil with Steelmaking Slag”

Tokyo, Japan – February 27, 2018 – Penta-Ocean Construction Co., Ltd. (hereinafter referred to as “Penta-Ocean”) is pleased to announce that we have developed “fiber reinforced calcia stabilized soil with steelmaking slag” (hereinafter referred to as “fiber reinforced calcia stabilized soil”), which has higher toughness than conventional one. The new technology was examined and certified, and Penta-Ocean was awarded a Certificate of Conformity Confirmation, in Service for Conformity Confirmation with the Technical Standards for Port and Harbor Facilities of Japan, by Coastal Development Institute of Technology.

Conventional calcia stabilized soil is a mixture of soft dredged soil, and calcia stabilized materials, which are made of steelmaking slag, conducted the component management, and particle size adjustment. It has features, such as strength development, suppression of turbidity, and alkali control. It is widely used as reclamation materials for filling in shallows and tidelands, alga field, and dredged trench, as technology to make effective use of steelmaking slag and dredged soil, which is generated as a by-product in the production process of steel, and dredging works respectively.

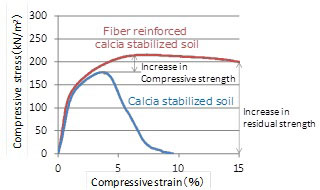

On the other hand, fiber reinforced calcia stabilized soil is produced, by mixing calcia stabilized soil with short fibers made from polyester and polypropylene, with the amount of 0.1 to 1% of the soil, as shown in Figure 1. The features of the fiber reinforced calcia stabilized soil are as follows:

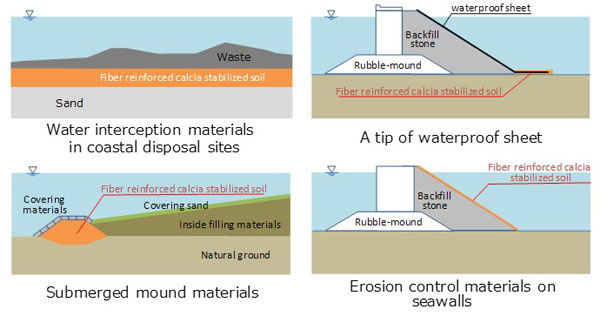

By taking advantage of these features above, it is possible to apply the fiber reinforced calcia stabilized soil to the following locations, where the conventional one is unable to be applied, as shown in Figure 4.

For construction works with the fiber reinforced calcia stabilized soil, after mixing the dredged soil, calcia stabilized materials and short fibers with a backhoe, or mixer, it is assumed to throw the mixture into the sea, by casting with a grab bucket, or tremie, as the same procedure with conventional one.

Although the fluidity of fiber reinforced calcia stabilized soil becomes smaller than that of conventional calcia stabilized soil, by adding short fibers, it has been verified that it is possible to mix, pump, and cast the fiber reinforced calcia stabilized soil, through an actual scale demonstration, using the same equipment as the actual construction.

For the results on these studies, committee of Conformity Confirmation with the Technical Standards for Port and Harbor Facilities of Japan (Zen Kouki, Chairperson, Specially Appointed Professor at Kyushu University, Graduate School of Engineering), consisting of academic experts, examined, and certified the fiber reinforced calcia stabilized soil. Consequently, Penta-Ocean was awarded a Certificate of Conformity Confirmation of “fiber reinforced calcia stabilized soil with steelmaking Slag”, in Service for Conformity Confirmation with the Technical Standards for Port and Harbor Facilities of Japan, by Coastal Development Institute of Technology.

In collaboration with Port and Airport Research Institute, Penta-Ocean has been currently reviewing the material characteristics of the fiber reinforced calcia stabilized soil. Penta-Ocean plans to apply the fiber reinforced calcia stabilized soil to social capital improvement works, as a construction method to promote effective utilization of dredged soil and steelmaking slag.

Figure 1 Materials of fiber reinforced calcia stabilized soil

Figure 2 Comparison between calcia stabilized soil and fiber reinforced calcia stabilized soil after unconfined compression test

Figure 3 Stress strain curve of calcia stabilized soil and fiber reinforced calcia stabilized soil

Figure 4 Usage examples of fiber reinforced calcia stabilized soil