This Page is Home![]() Updates

Updates

What's New

Penta-Ocean Construction Co., Ltd.

Takuzo Shimizu, President, CEO and Representative Director

Penta-Ocean Construction Developed a System for Inspecting and Diagnosing Pier Undersurfaces: Supporting Maintenance Work Management of Piers with ICT and Image Processing Technology

Tokyo, Japan – January 16 2018 - Penta-Ocean Construction Co., Ltd. is pleased to announce that we have developed an unmanned system for remotely inspecting and diagnosing the under surfaces of the piers.

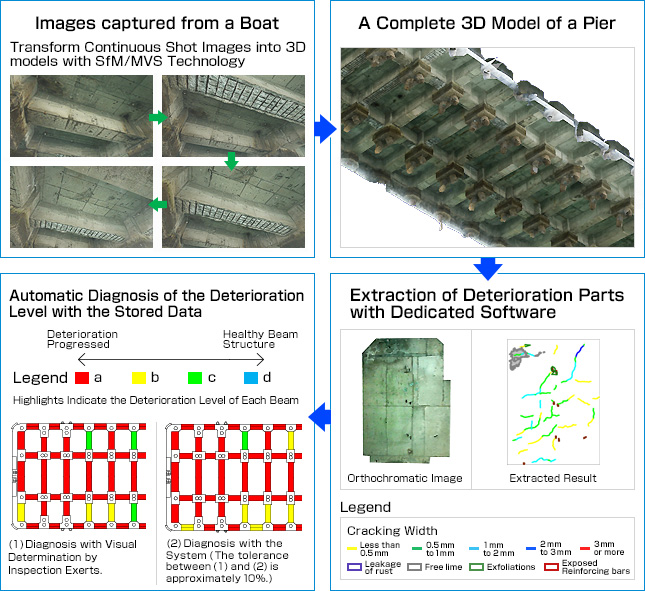

Using the system, “A wireless LAN boat”, (a tentative name) is navigated under a pier to capture the images of the deteriorated parts on the pier with a mounted camera. By transforming the captured images into 3D models, the locations of defects, such as cracks and exfoliations, are accurately detected, which helps diagnose the deterioration level automatically.

Meanwhile, according to the conventional inspection method, a few inspectors got onto a small boat and grasped the deterioration level by observing piers from the boat, capturing images, and drawing sketches. Sometimes the time for inspection was limited, affected by the tidal level. Furthermore, it was only the inspection experts who were able to assess the deteriorated parts with the captured images and drawn sketches.

In contrast to this, “A wireless LAN boat”, with a length of 2.2 meters is navigated remotely and wirelessly to operate a camera for capturing images. The camera is equipped with a high-performance Gimbal (oscillation suppression device), which prevents the camera from vibrating due to waves, and helps capture stable images. After that, a 3D model*¹ is constructed with the captured images by adopting the technology of Structure from Motion (SfM) and Multi-View Stereo (MVS). Then, with the 3D model, the deterioration level is automatically diagnosed in accordance with the determination criteria, including crack density, existence, or nonexistence of exfoliation areas, and proportion of the area exposed reinforcing bars, with dedicated software. Furthermore, it is able to acquire the Computer-Aided Design (CAD) drawings that depict the 3D model and cracks, as well as Construction Information Modeling (CIM) *² that incorporates the deterioration level of inspected parts, whose data is stored for maintenance work management.

The features of the system are as follows:

1. Can conduct safe, objective, and unmanned inspection and diagnosis even in a narrow place under piers

2. Can implement inspection 2.5 times faster than manual inspection

3. Can get into narrow places, and be hardly affected by tidal levels

4. Can identify deteriorated parts properly by 3D modeling images, and the deterioration due to aging can be easily compared if regularly inspected

5. Can diagnose the deterioration level automatically and objectively with dedicated software

From now on, we plan to promote the system proactively to save labor on construction sites, and submit efficient maintenance and management proposals to our clients by taking advantage of Information & Communication Technology (ICT), which is applied to the system, instead of the conventional manual procedure carried out by inspection experts.

Please note that the system was adopted by SIP “Infrastructure Maintenance, Renovation, and Management” (Management Agency: NEDO) of Council for Science, Technology and Innovation at the Cabinet Office, Government of Japan, to research and develop.

*1: Data, where the targeted structure figures are represented in 3D models, according to CIM Guideline by Ministry of Land, Infrastructure, Transport, and Tourism

*2: CIM is a combination of “3D models”, where the targeted structure figures are represented in 3D models, and “attribute information”, according to CIM Guideline by Ministry of Land, Infrastructure, Transport and Tourism

A wireless LAN boat (a tentative name)

Deterioration Diagnosis Procedure