This Page is Home![]() Updates

Updates

What's New

Penta-Ocean Construction Co., Ltd.

Development of a Calcia Bucket to improve efficiency in mixing operation of Calcia improved soil

Tokyo, Japan - July 18, 2023 - Penta-Ocean Construction Co., Ltd. (President: Takuzo Shimizu, hereinafter POC) and Ishimoto Kensetsu Co., Ltd. (President: Akihisa Ishimoto) have jointly developed a Calcia Bucket which improves the mixing capacity of Calcia improved soil, and registered it under the New Technology Information System (NETIS KKK-20000-A). The new Calcia Bucket is a skeleton bucket with a three-layer grating bottom (upper, middle and bottom). With this invention, one mixing operation allows the material inside to pass through three layers of grills , performing efficient operation when loosening dredged soil using a backhoe or when mixing sludge with Calcia improved soil.

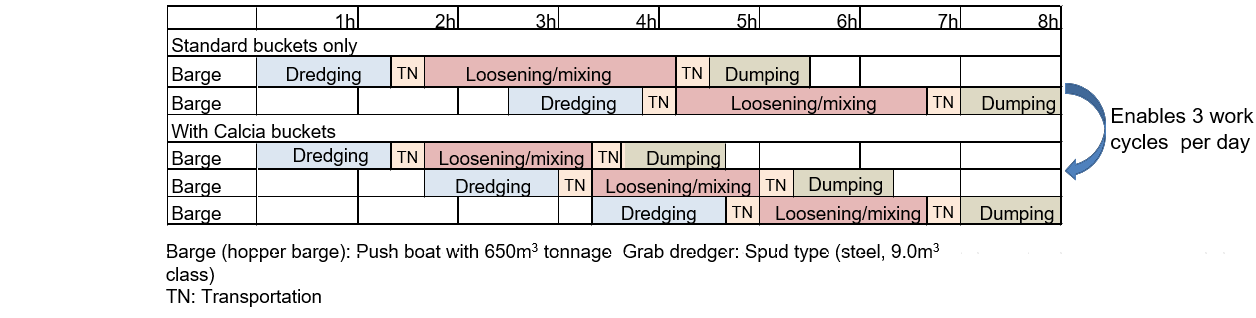

The Calcia improved soil is a mixture of soft dredged soil and Calcia improving material (steelmaking slag with controlled component ratio and particle size) and exhibits the strength-enhancement and turbidity controlling features, mainly used for reclamation and backfilling in shallows and tidelands. The Calcia improved soil is produced after an operation cycle of dredging, sludge break-up, mixing and dumping, as illustrated in Fig-2. The two processes of breaking up the dredged sludge on board the hopper barge and the mixing by adding the Calcia improved soil consume half of the time required for the entire process. Moreover, because the Calcia improved soil hardens gradually after the production, the whole process through to the deposition must be completed quickly.

Conventionally, the processes of sludge break-up and mixing were generally performed by two backhoes on board the hopper barge moored to the quay wall. According to a study of 10 cases of measuring mixing time when using one Calcia Bucket and one standard bucket concurrently, we confirmed the improvement in mixing capacity compared to using two standard buckets, and the time required for mixing was reduced to approximately two thirds as shown in Figure 3.

Additionally, while sludge break-up and mixing using only conventional buckets can be performed up to two cycles per day, the additional use of a Calcia Bucket enables three cycles of operations per day, eliminating waiting time for dredging and thereby making a significant contribution to productivity improvement (Figure 4).

Currently, POC owns three sizes (0.8m3, 1.9m3 and 3.1m3) of Calcia Buckets, and the user can choose the one that best fits the needs depending on the size of the hopper barge or the scale of construction projects. Going forward, we will actively utilize Calcia Buckets to achieve efficient construction of social infrastructure using Calcia improved soil.

■Features■

(1) Reduces time required for mixing Calcia improved soil to two-thirds

(2) Increases the amount of construction work performed in one day by approx. 1.5 times

(3) Applicable to the production of different types of improved soil using other additives (cement etc.) than Calcia improving material

Figure 1 Calcia Bucket and operation status

Figure 2 Construction flow when producing Calcia Improved Soil by a backhoe

Figure 3 Reduction of mixing time when adding a Calcia Bucket

Figure 4 Change in operation cycle when adding a Calcia Bucket