This Page is Home![]() Updates

Updates

What's New

Penta-Ocean Construction Co., Ltd.

Development of the Joint Interface Method of Columns with Non-Uniform Widths

- Group of nine companies obtained the structural performance evaluation

of this method promoting a cost-effective design method -

Tokyo, Japan - May 26, 2023 - Asunaro Aoki Construction, Asanuma Corporation, Hazama Ando Corporation, Kitano Construction Corporation, Konoike Construction, Penta-Ocean Construction, Tekken Corporation, Haseko Corporation and Yahagi Construction jointly obtained a structural performance evaluation (ERI-K22001*1) on the Joint Interface Method of Columns with Non-Uniform Widths from Japan ERI Co., Ltd.

The Joint Interface Method of Columns with Non-Uniform Widths enhances the flexibility of design and reduces cost compared to conventional methods in the construction of steel-framed structures with widths of square steel columns that vary between upper and lower floors.

[Research background]

In the construction of steel-framed buildings, certain scenarios arise where the top floor roof is comparatively lightweight, as seen in warehouse structures, or in cases where the intended use and floor heights differ between upper and lower floors. In such instances, it becomes necessary to adjust the column width of the upper floor to be smaller than that of the lower floor.

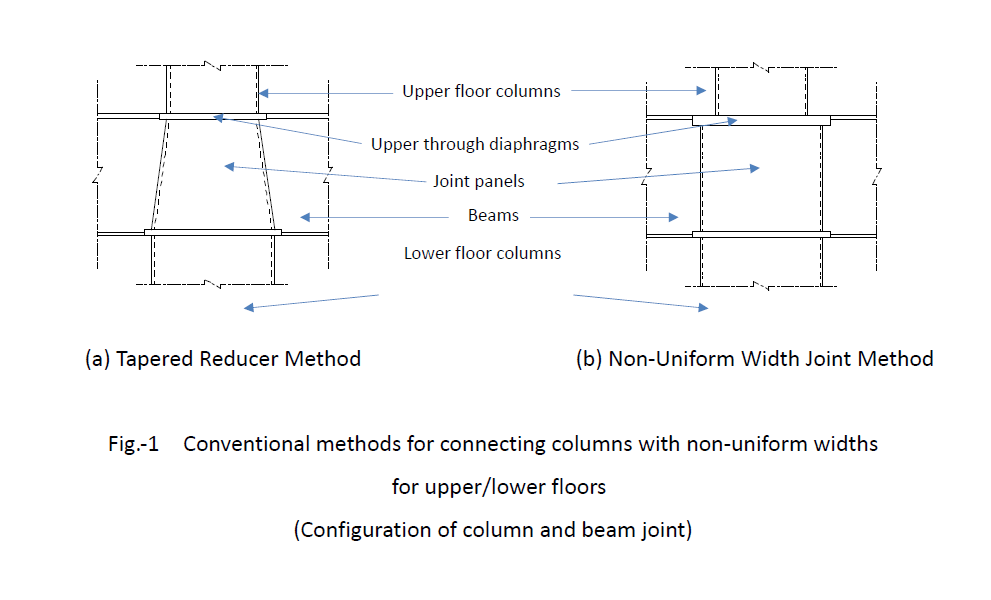

Conventionally, tapered reducers (tube diameter is reduced towards the upper edge) have been utilized in the joint section panel zones in cases where the widths of the square steel columns for the upper and lower floors were different. (Figure-1(a)).

However, this method was accompanied by manufacturing complexities and the need for meticulous attention to a possible cost escalation and delivery timelines.

Alternatively, in some cases, the Non-Uniform Width Joint Method (Figure- 1(b)) was adopted,

in which the upper-floor columns are simply connected to the joint panel via upper through diaphragms*2. However, the width difference between the upper and lower floor columns is limited to 50 mm by AIJ Recommendations for Connections in Steel Structures, issued by the Architectural Institute of Japan.

*1 Japan ERI Corporation, a third-party inspection agency specializing in the construction field, conducted the inspection in accordance with the Building Standard Act and other technical standards.

*2 Through-diaphragm: A steel plate used to connect steel columns, beams, and joint panels.

[Overview of the Joint Interface Method of Columns with Non-Uniform Widths]

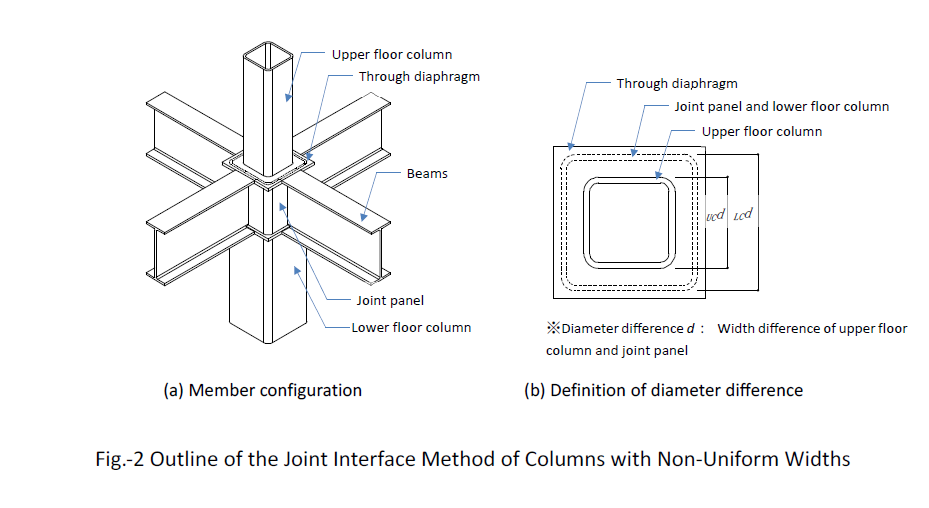

The Joint Interface Method of Columns with Non-Uniform Widths (Figure-2) is a technology developed to handle substantial difference in square steel column widths when applying the “Non-Uniform width Joint Method”, aiming for more cost-effective and rational construction of buildings.

By implementing the design principles of the Joint Interface Method of Columns with Non-Uniform Widths, it becomes possible to achieve a maximum width difference of 150mm between the upper floor column, the joint panel and the lower floor column, while ensuring that the through diaphragm remains structurally stable, and do not fail prior to the upper

floor column through the appropriate adjustments of through-diaphragm plate's thickness.

Furthermore, the applicable widths of the joint panels and lower floor column sizes are between 300 mm and 800 mm.

[Cost comparison with the conventional construction method]

The implementation of the Joint Interface Method of Columns with Non-Uniform Widths offers a significant cost reduction effect, approximately JPY 100,000 per column-beam joint compared to the conventional method (the Tapered Reducer Method.)

[Future Prospects]

In the future, each participating company intends to adopt the Joint Interface Method of Columns with Non-Uniform Widths in various building types such as office buildings, commercial facilities and logistics warehouses, particularly in the intermediate and uppermost floors, with the objective of promoting the widespread adoption of this innovative method.