This Page is Home![]() Updates

Updates

What's New

Penta-Ocean Construction Co., Ltd.

Takuzo Shimizu, President, CEO and Representative Director

Precast Pier Caps for Enhanced Productivity

Tokyo, Japan – Novmber 13, 2018 – Penta-Ocean Construction Co., Ltd. (hereinafter “Penta-Ocean”) was awarded a pier construction work contract by The Tohoku Regional Development Bureau of Ministry of Land, Infrastructure, Transport and Tourism. We were granted approval to employ Sleeve Connection Method for this project, which is considered the most applicable solution for installation of precast pier caps.

Because the conventional construction of pier caps involves a series of works over water – driving of steel-pipe piles, assemblies of scaffolding, form timbering, rebar as well as on-site concrete casting – the process is largely affected by maritime weathers such as tidal level and wave height. The off-site prefabrication of pier caps therefore significantly reduces construction time and labor on-site. Changing to prefabrication should also lead to superior product quality and a higher safety profile of pier caps.

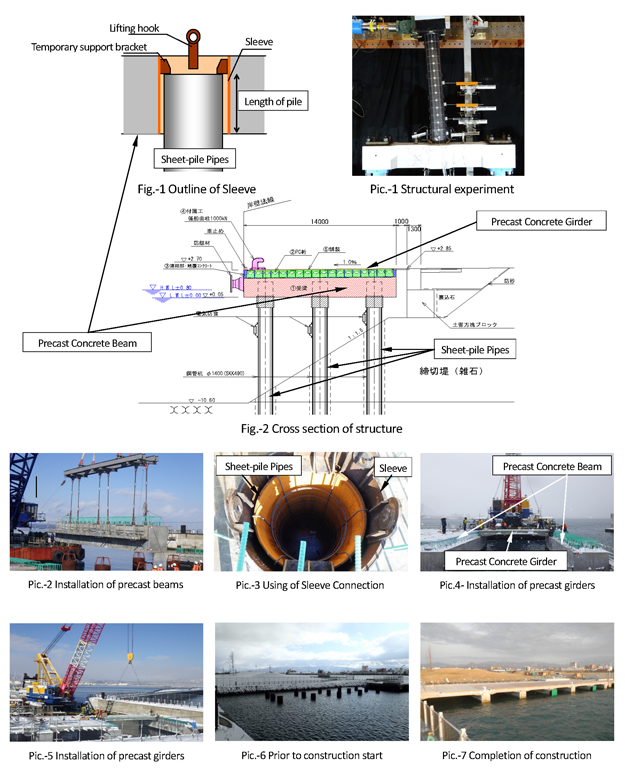

The main technical issue in pier cap prefabrication would be the connection between the pier caps and the steel-pipe piles at the pile heads. This time we adopted Sleeve Connection Method which ensures rigid connection without sacrificing on-site workability. In this method, we embed in precast pier caps some hollow steel casts (sleeves) with diameters larger than that of steel-pipe piles. When installing the pier caps from a crane barge on-site, the elements are connected by inserting the pipes into the sleeves which have the depth corresponding to the pile diameter, and then are completely spliced by injecting non-shrinking concrete into the sleeve pockets.

We have conducted a series of structure experiments concerning the yield strength of pile head connection when using this method, jointly with National University Corporation Tokyo Institute of Technology and National Institute of Maritime, Port and Aviation Technology / Port and Airport Research Institute (PARI). Compared to the conventional cast-in-place connection method, Sleeve Connection Method was proven to show better pile-head connection rigidity as well as higher energy absorption property.

Sleeve Connection Method demonstrates below features (in comparison with the conventional cast-in-place pier caps)

- 1)Construction time reduction ⇒ shortened by 30 %

- 2)Pile-head connection rigidity enhancement ⇒ 1.6 times superior (in case of design against level-2 earthquake motion)

- 3)Energy absorption feature enhancement ⇒ 2 times superior

The Sleeve Connection Method provides the best solution for precast cap installation, as the method transmits the same amount of seismic inertia force on the superstructure as the conventional on-site casting method, without the need of special redesigning of substructure.

In this particular project, precast beams were connected to steel-pipe piles by Sleeve Connection Method, followed by the installation of precast girders fabricated off-site. The elements were then entirely integrated by running along PC (Prestressed Concrete) strands.

1)Pile Head Connection Rigidity: An index measured by the relative rotation angle of the steel-pipe piles and the pier caps. The smaller the angle is, the higher the rigidity.

2) Energy Absorption Property: The external force energy is absorbed by the response deformation of pile heads. An indicator that shows tenacity in plastic zones.

3) Level 2 Earthquake motion: The strongest possible earthquake motion expected in the target region.