This Page is Home![]() Technologies and Innovation

Technologies and Innovation![]() Civil Engineering Technology

Civil Engineering Technology![]() Pipe Mixing Method

Pipe Mixing Method

Pipe Mixing Method

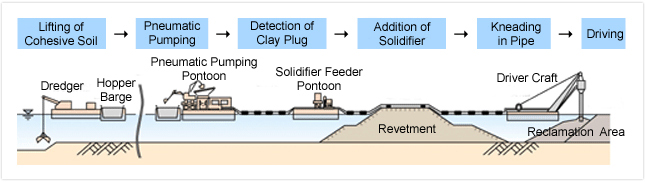

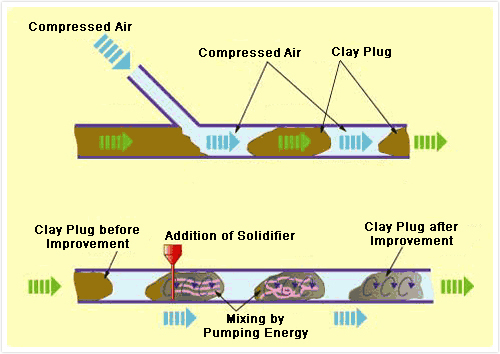

Owing to the persistent lack of space in Japan, it has become increasingly difficult to obtain space at disposal sites for dredged soil. For this reason, systems such as the Pneumatic Flow Mixing Method have been developed to recycle it as a value-added, lightweight high-strength material for use in reclamation work, or as backfill behind bulkheads. Using this method, water-added dredged soil is mixed with cement slurry inside the pipeline by means of turbulent flow generated during its transport. Aiming to further improve this method, Penta-Ocean have developed the Pipe Mixing Method, which can realize more stabilized quality of treated soil by equipping quantitative analysis instruments for cement supply.

High efficiency in mixing of slurry and soil

Since solidifier slurry is added directly to cohesive soil while pumping it through pipes, high efficiency mixing of the slurry and soil can be achieved.

Large-scale treatments

A standard-type pneumatic transfer vessel can be used so that dredged soil in significant quantities can be treated simultaneously.

Soil improvement operations not required after reclamation

This method allows treatment of soil dredged soil and reclamation work to be carried out simultaneously, eliminating the need for soil improvement after completion of the reclamation process.