This Page is Home![]() Technologies and Innovation

Technologies and Innovation![]() Civil Engineering Technology

Civil Engineering Technology![]() The Key Element Method – Final Joint for a Immersed Tunnel

The Key Element Method – Final Joint for a Immersed Tunnel

The Key Element Method – Final Joint for a Immersed Tunnel

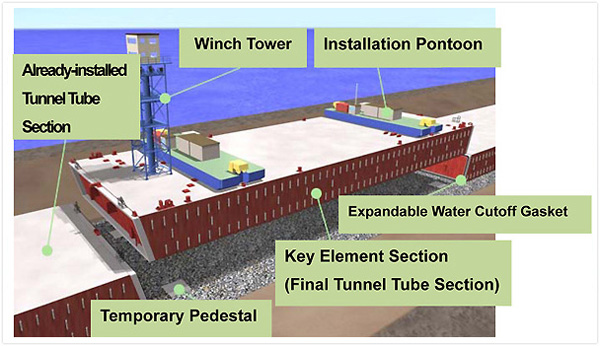

The Key Element Method is an advanced technology based system for installing the final and most critical segment in submerged tunnel construction. Installation of the final segment has been conventionally performed utilizing a cofferdam, with diver’s applying the V-block method also developed by Penta-Ocean. The new procedure utilizes the final tunnel section itself as the jointing element, eliminating the need for diver assisted final joint construction work. This method is a substantial improvement over conventional final joint construction methods in terms of the reductions in construction time and cost, and quality and safety.

Shortening construction time

Since conventional V-Block final jointing work is eliminated, construction time can be shortened by approximately three months.

Submerging facilities similar to those for ordinary undersea tunnels

The Key Element Method uses similar submerging components as those for ordinary tunnels, eliminating the need for large-sized floating cranes and requiring smaller working perimeters, making the system ideal for work in areas subject to height restrictions, such as airports.

Flexible for handling construction errors

Longitudinal errors can be absorbed using a hollow, expandable water cutoff gasket that can be expanded by injecting air or mortar.